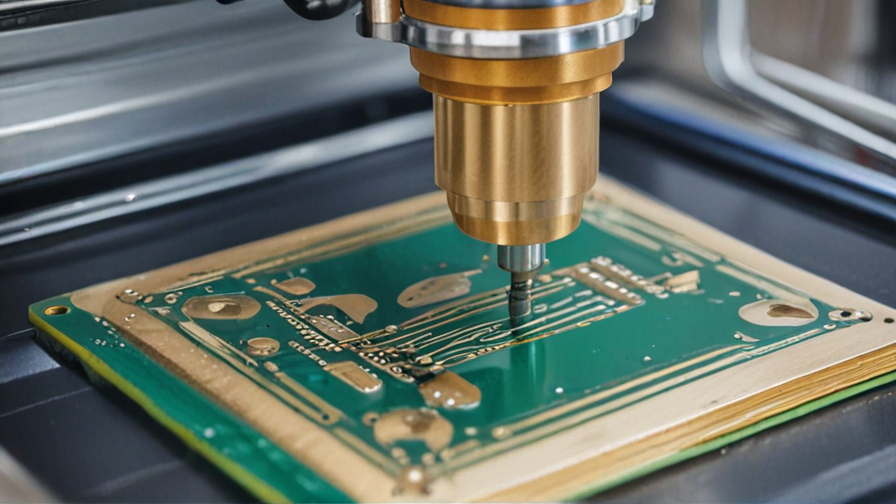

We understand that milling printed circuit boards (PCBs) requires specific tools and techniques to achieve optimal results. In this post, we’ll delve into the types of bits you should consider for PCB milling, helping you make informed decisions for your projects.

▎Understanding PCB Milling

PCB milling is a subtractive manufacturing process that involves removing material from a substrate to create traces, pads, and vias for electronic circuits. This process is commonly employed in prototyping and small-scale production of PCBs. The choice of milling bits plays a crucial role in determining the precision, quality, and efficiency of your PCB fabrication.

▎Types of Bits for PCB Milling

When it comes to PCB milling, there are several types of bits that are commonly used. Each type has its own specific applications and advantages. Here’s a breakdown of the most popular bits for PCB milling:

Description: End mills are versatile cutting tools with cutting edges on both the end and sides. They come in various diameters and flute configurations.

Recommended Use: For general PCB milling tasks, including cutting traces and pads. A 1/32″ or 1/64″ end mill is ideal for fine details.

Advantages:

• Good for creating complex shapes.

• Available in various materials (HSS, carbide) for different applications.

Description: V-bits have a pointed tip that allows for engraving and cutting at angles. They are available in various angles, typically ranging from 30° to 90°.

Recommended Use: Ideal for creating fine details, such as text or intricate designs on PCBs.

Advantages:

• Capable of producing sharp corners and detailed features.

• Excellent for engraving designs on the surface of the PCB.

▎3. Drill Bits

Description: Drill bits are specifically designed to create holes in materials. For PCBs, micro drill bits with small diameters (e.g., 0.3mm to 1.0mm) are often used.

Recommended Use: For creating vias and mounting holes on the PCB.

Advantages:

• Precision drilling for accurate hole placement.

• Available in various sizes to accommodate different hole requirements.

▎4. Router Bits

Description: Router bits have a cylindrical shape and are used primarily for edge profiling and surface finishing.

Recommended Use: While not as common for PCB milling, router bits can be used for cutting larger areas or profiles on thicker substrates.

Advantages:

• Effective for larger cuts where precision is less critical.

• Can help achieve smooth edges on thicker materials.

▎5. Specialty Bits

Description: These bits are designed for specific applications, such as micro-milling or high-speed machining.

Recommended Use: Depending on your specific project requirements, specialty bits can enhance efficiency and precision.

Advantages:

• Tailored for unique applications.

• Often designed to reduce wear and improve longevity.

▎Material Considerations

When selecting bits for PCB milling, it’s essential to consider the material of both the bit and the PCB substrate. Common materials include FR-4 (a glass-reinforced epoxy laminate), aluminum, and copper.

▎Bit Material Options:

• High-Speed Steel (HSS): Good for softer materials but may wear out quickly on tougher substrates.

• Carbide: More durable and suitable for a wider range of materials, including harder substrates.

▎Tips for Successful PCB Milling

1. Choose the Right Speed and Feed Rates: Adjusting your spindle speed and feed rates according to the bit type and material will significantly impact the quality of your cuts.

2. Use Proper Cooling Techniques: Cooling is crucial to prevent overheating and damaging both the bit and the PCB material.

3. Test Cuts: Always perform test cuts on scrap material to fine-tune your settings before working on your actual PCB.

4. Maintain Your Bits: Regularly inspect and replace worn bits to ensure consistent performance.

▎Conclusion

Choosing the right bits for PCB milling is essential for achieving high-quality results. At Maple CNC, we offer a wide range of CNC parts and accessories tailored to meet your PCB milling needs. Whether you’re a hobbyist or a professional engineer, understanding the various types of bits available will help you make informed decisions that enhance your projects.

If you have any questions or need assistance selecting the right tools for your next PCB milling project, feel free to reach out to our knowledgeable team at Maple CNC.