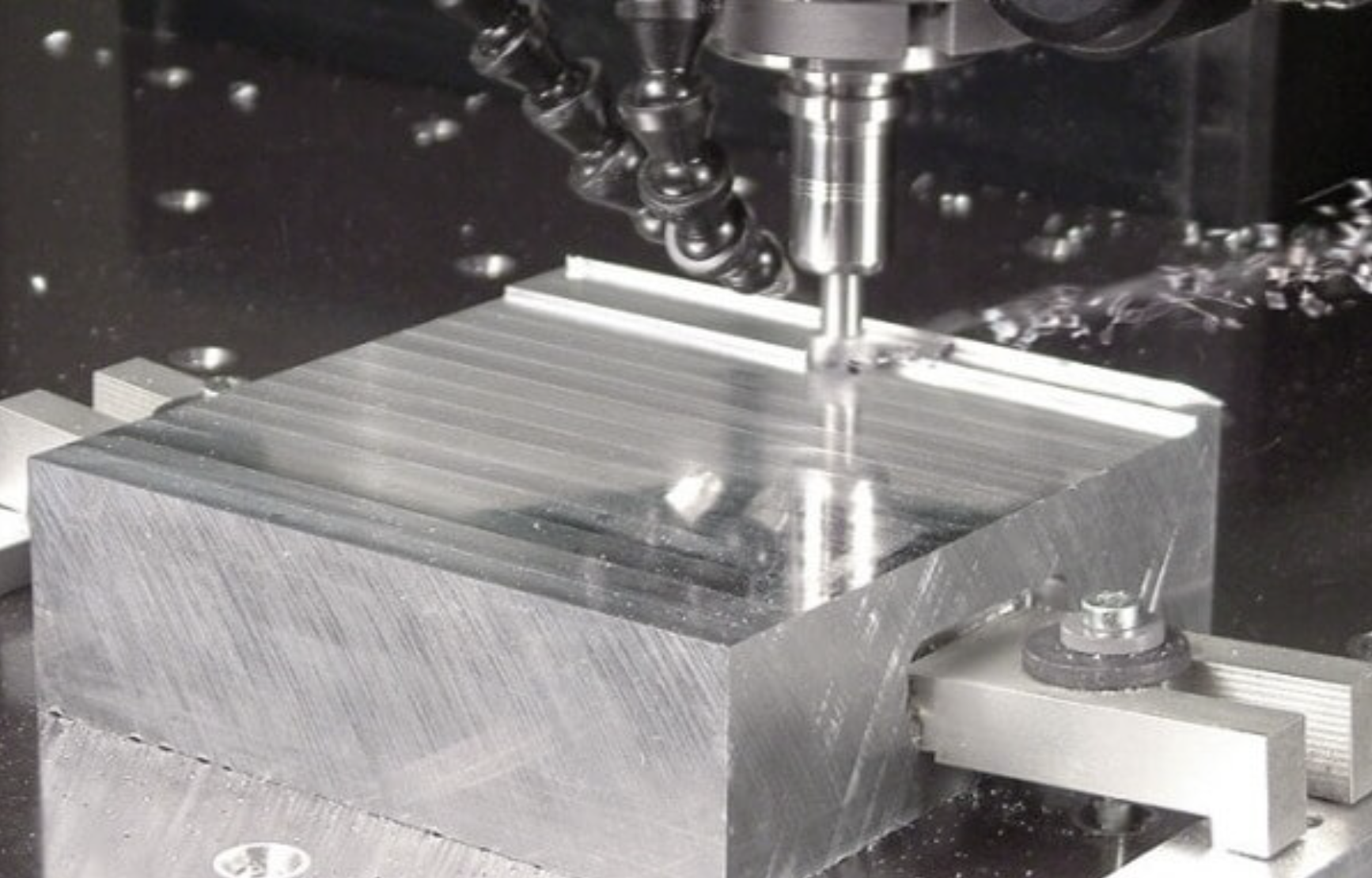

Welcome to the Maple CNC blog, where we provide insights and tips for CNC machining enthusiasts and professionals alike. If you’re involved in machining aluminum, understanding the right RPM (Revolutions Per Minute) and selecting the appropriate bit are crucial for achieving optimal results. In this article, we’ll explore the ideal RPM for machining aluminum and recommend the best bits for your CNC projects.

Understanding RPM in CNC Machining

RPM refers to the number of revolutions a cutting tool makes in one minute. In CNC machining, the correct RPM is vital for ensuring efficient cutting, maintaining tool longevity, and producing high-quality finishes on your workpiece.

Factors Influencing RPM

1. Material Type: Different materials require different RPM settings. Aluminum is softer than steel or titanium, allowing for higher RPMs.

2. Bit Diameter: The diameter of the cutting tool affects the optimal RPM. Larger bits generally require lower RPMs to avoid overheating.

3. Feed Rate: The speed at which the material is fed into the cutter also plays a role in determining the ideal RPM.

Recommended RPM for Machining Aluminum

For aluminum machining, the recommended RPM typically falls within the range of 8,000 to 20,000 RPM. However, the specific RPM you should use depends on several factors:

• Bit Diameter:

• For a 1/8″ bit, an RPM of around 18,000 to 20,000 is ideal.

• For a 1/4″ bit, aim for about 12,000 to 15,000 RPM.

• For larger bits (1/2″ or more), reduce the RPM to around 8,000 to 10,000.

• Type of Aluminum: Different aluminum alloys may require slight adjustments in RPM. Softer alloys can handle higher speeds, while harder alloys may necessitate lower speeds.

Example Calculation

To determine the optimal RPM using the formula:

RPM = (CS × 12)/(π × D)

Where:

• CS = Cutting Speed (in feet per minute)

• D = Diameter of the cutter (in inches)

For aluminum, a typical cutting speed (CS) is around 600-1200 SFM (Surface Feet per Minute).

For instance, if you’re using a 1/4″ bit:

• Using a CS of 1000 SFM:

RPM = (1000 × 12)/(π × 0.25) ≈ 15200 RPM

This calculation supports the general recommendation of operating between 12,000 to 15,000 RPM for a 1/4″ bit.

Recommended Bits for Machining Aluminum

Choosing the right bit is just as important as setting the correct RPM. Here are some recommended types of bits for machining aluminum:

1. Carbide End Mills

Carbide end mills are ideal for machining aluminum due to their hardness and durability. They provide clean cuts and can withstand higher speeds without wearing down quickly.

2. Two-Flute End Mills

Two-flute end mills are particularly effective for aluminum because they allow for better chip removal. This prevents clogging and overheating during the machining process.

3. Single-Flute End Mills

For high-speed operations, single-flute end mills can be advantageous as they provide maximum chip clearance. They are especially useful when machining softer grades of aluminum.

4. Ball Nose End Mills

If you’re looking to create curved surfaces or intricate designs in aluminum, ball nose end mills are an excellent choice. They provide smooth finishes and are versatile for various applications.

Conclusion

Machining aluminum requires careful consideration of both RPM and the type of bit used. At Maple CNC, we offer a wide selection of high-quality CNC bits designed specifically for aluminum machining. By following the recommended RPM guidelines and choosing the right bit, you can achieve superior results in your projects.

Ready to enhance your CNC machining experience? Explore our collection at Maple CNC today and find the perfect tools to take your projects to the next level!