CNC routers have become essential in precision manufacturing in Canada due to their versatility and efficiency. These computer-controlled machines serve as a modern substitute for traditional hand-held routers. With advanced software and automation, CNC routers Canada minimize errors and boost production, benefiting both professionals and hobbyists. This article examines the components and functionality of CNC routers which are vital in today’s manufacturing industry.

What Is a CNC Router?

A CNC, Computer Numerical Control, is a computer-controlled machine designed for tasks like milling, drilling, and cutting various materials. While they share similarities with milling machines, many CNC routers can perform nearly identical functions. Their primary roles include cutting, engraving, and carving shapes from a workpiece. The use of computer control greatly reduces the likelihood of operational errors.

CNC routers Canada come in different sizes and configurations, featuring one or more axes for movement and the capability to change tools for various tasks. The standout aspect of these machines is their computer control, which directs the movement, rotation, and spinning of tools based on a CAM (Computer-Aided Manufacturing) program.

This program can be created manually for simpler jobs or generated automatically through specialized software. The software converts a digital CAD (Computer-Aided Design) file into a series of instructions that guide the machine in completing its tasks.

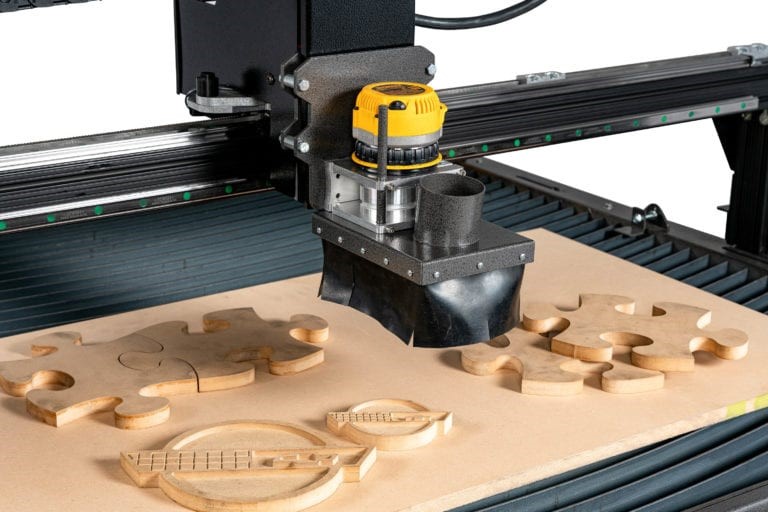

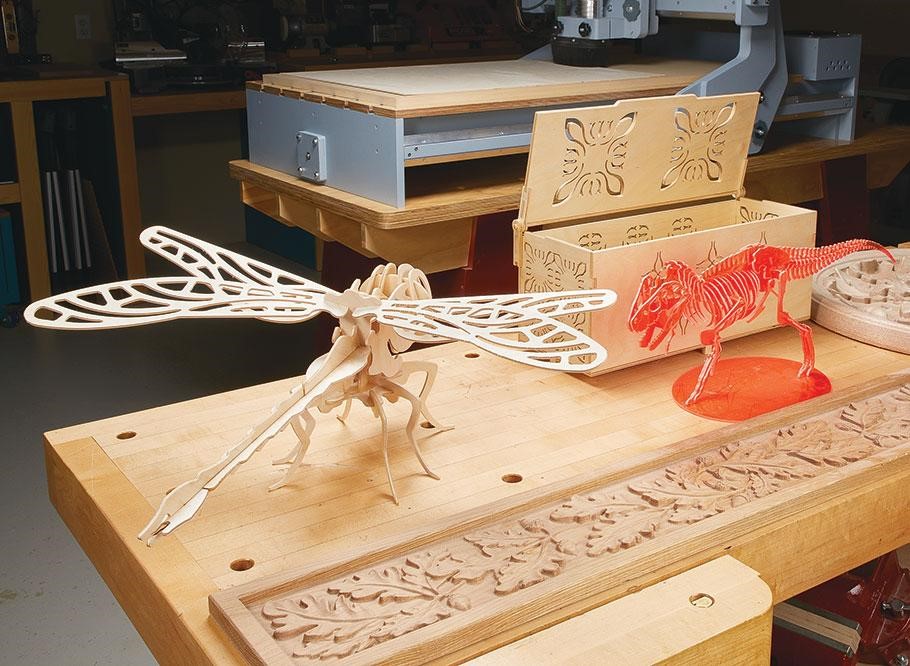

CNC routers Canada are essential in woodworking, allowing for the production of an array of items, from cabinet doors to detailed 3D sculptures. They can also create wooden patterns for sand molds used in metal casting and can carve foam into distinctive shapes for packaging applications.

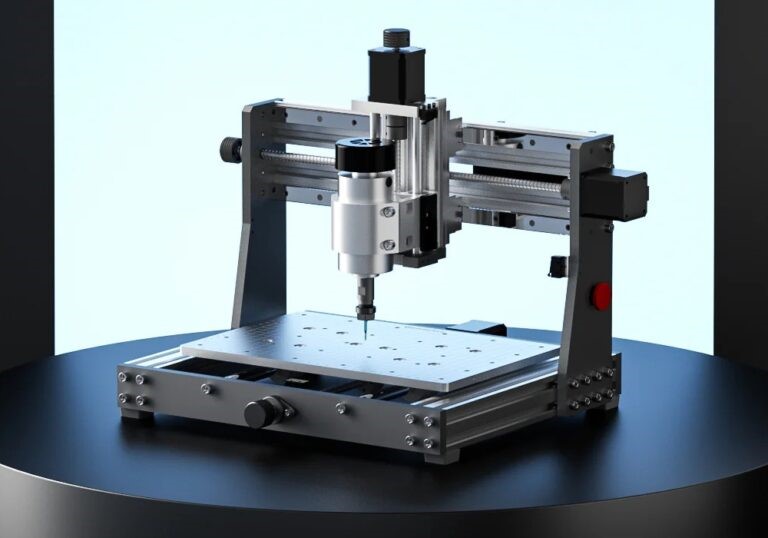

Different Parts of a CNC Router

To truly grasp how a CNC router works, you need to understand its various parts and how they contribute to the whole functionality. Each component is a key in the machine’s performance and flexibility.

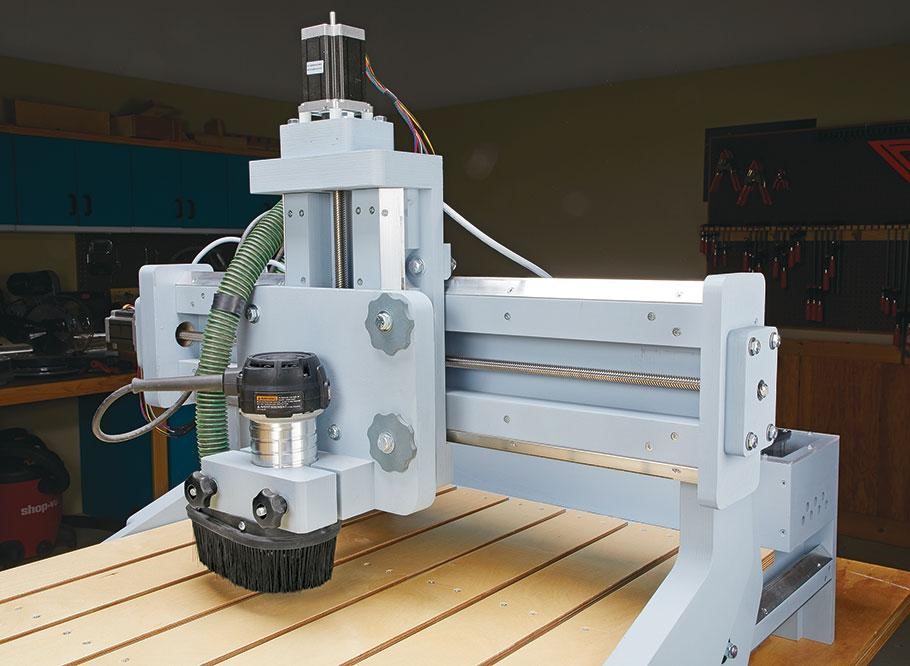

Frame

Think of the frame as the foundation of the CNC router Canada. It provides the necessary support for the entire machine and needs to be strong and stable to handle the forces involved during routing. A sturdy frame is vital for achieving accurate cuts, as any bending or vibrations can result in errors.

Motors

The motors are what power the CNC router, enabling movement along the X, Y, and Z axes. Typically, stepper and servo are two main types of motors used in these machines. Stepper motors operate in fixed increments, allowing for precise positioning without needing feedback.

On the other hand, servo motors come with feedback systems that help correct any differences between where the machine is supposed to be and where it actually is, providing even higher levels of accuracy and efficiency.

CNC Controller

The controller in the CNC router Canada acts as the machine’s brain. This computerized panel takes the G-code generated by CAM software and converts it into electrical signals that guide the motors. It serves as the control center where you can enter commands and keep an eye on the routing process, ensuring that the machine follows the design accurately.

Gantry

The gantry is like a bridge that stretches over the cutting area of the CNC router Canada. It holds the spindle or router and can move side to side (X-axis), and in some designs, it can also move front to back (Y-axis). The gantry must be stable enough to operate smoothly for making precise cuts and detailed designs.

Table/Bed

The table, often called the bed, is where you secure the material you want to work on. It’s designed to be flat and stable, accommodating different materials using clamps, vacuum systems, or other methods to hold everything in place. The way the table is designed is important because it affects what materials you can use and how accurate your cuts will be.

Spindle/Router

The spindle or router is the main cutting tool of the CNC router Canada, responsible for carving, engraving, and shaping the material. These tools come in various power levels and speed settings, allowing for a wide range of cutting tasks, from delicate engraving to deeper, more aggressive cuts.

Ways

“Ways” refers to the linear guides or bearings that help the machine’s parts move smoothly and accurately along different axes. High-quality ways reduce friction and wear, which is important for maintaining the CNC router’s long-term accuracy and reliability.

Axis Drive

The axis drive system in a CNC router Canada, which can include setups like rack and pinion or ball screws, converts the motors’ rotational motion into linear movement. This movement is what moves the gantry and router across the material. The type of drive system you choose can greatly affect the machine’s speed, precision, and ability to work with various materials.

How Does a CNC Router Function?

As it was mentioned earlier, a CNC router utilizes servo motors that receive instructions in a specific programming language known as G-code. This code guides the machine on how to move and where to cut. To operate a CNC router Canada for material processing, you should adhere to the following steps:

- Begin by utilizing the CAD (computer-aided design) software that accompanies the machine to craft the design intended for cutting.

- Subsequently, transition to the toolpath software provided with the machine to generate the essential cutting instructions.

- Secure the material firmly to the cutting bed, employing the most suitable method based on the type and dimensions of the material.

- Select and install the appropriate router bit. A variety of CNC router bits are available, each tailored for specific cutting tasks, such as:

Spiral bits, which excel in lateral wood cutting.

Straight bits, ideal for chamfering and finishing edges.

Elongated knife bits, crafted for slicing through various materials.

- Finally, initiate the routing process. The spindle will move in accordance with the programmed instructions, navigating through three dimensions to achieve the desired cuts.

Why a CNC Router?

A CNC router Canada comes with many benefits including the following:

Different Methods for Production

CNC routing is widely used in various fields such as woodworking, signage, moldings, and thermoforming in which it excels in producing precise cuts consistently.

Use of Various Materials

CNC routers can work with a range of hard materials such as wood, metal, stone, plastics, foam, acrylic, and glass.

High Quality Production in No Time

These machines significantly reduce production time and minimize manufacturing errors, allowing for the creation of nearly identical objects every time, as long as external factors are controlled.

Different Models and Different Sizes

Unlike older, bulky models, modern CNC routers Canada come in various sizes, including compact desktop versions that can fit on a table while still delivering high-quality results.

Easy to Use Software

Advances in software have made it easier for hobbyists to operate CNC routers. CAD/CAM programs are available to help create simple models and generate design codes, making these machines accessible to tinkerers, furniture makers, and designers without requiring professional woodworking skills.

Conclusion

CNC routers Canada have truly changed the game in Canada’s manufacturing scene. They provide incredible precision, efficiency, and versatility for a variety of tasks. Whether you’re a professional in fields like woodworking or signage, or a hobbyist working on creative projects, CNC routers can handle a wide range of materials and jobs. To get the best machine suitable for you job or project it’s recommended to seek help from experts in this area.