CNC milling machines are versatile tools used in various industries to shape materials through controlled cutting. By understanding how to use a CNC mill, operators can efficiently remove material from a workpiece using rotating cutting tools and precise computer-controlled movements. CNC milling is a cornerstone of modern manufacturing, be it aerospace and automotive or medical and precision engineering.

What Is a CNC Milling Machine?

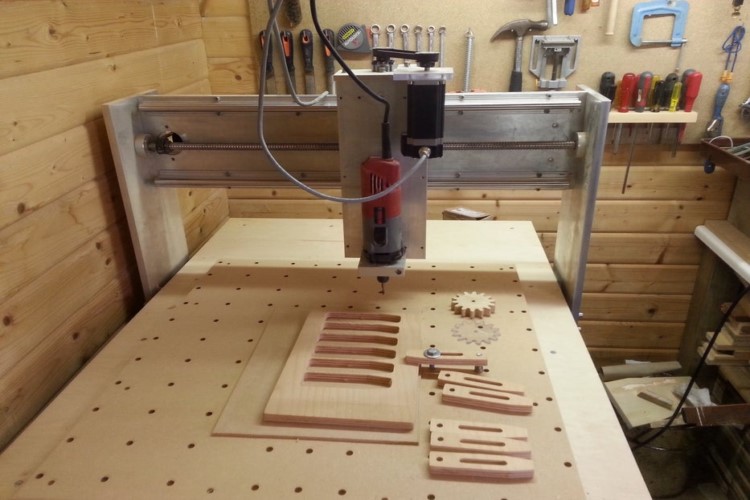

CNC milling machines are precision cutting tools that utilize Computer Numerical Control (CNC) systems to meticulously remove material from a workpiece to create accurately crafted parts designed with computer-aided design (CAD) software. These machines and their cutting bits typically feature a main spindle and three linear axes for precise positioning, with advanced models incorporating additional rotational axes for creating intricate shapes.

The how-to use a CNC mill process involves securing a pre-shaped workpiece onto a fixture, where a high-speed rotating tool chips away material to achieve the desired shape. The choice of material and the complexity of the part dictate the use of different axes, cutting speeds, and feed rates.

Milling is especially effective for producing components with unique curvatures or surface contours, and it plays a crucial role in manufacturing processes, including the creation of 3D molds.

CNC Milling Machine Features

Historically, milling machines relied on manual operation, requiring operators to juggle multiple machines equipped with various tools to create intricate parts or products. They often had to adjust numerous settings on a single machine to complete their tasks.

However, with technological advancements like CNC controls and Automatic Tool Changers (ATCs), the landscape has transformed. These innovations enable enhanced efficiency, flexibility, and speed, even when dealing with complex components. The introduction of digital readouts and measuring systems as well as how to use a CNC mill guide has significantly boosted the precision of CNC machining processes.

To meet the needs of manufacturers who demand the adaptability of “High Mix, Low Volume” (HMLV) or “small batch” production, CNC machining centers can now be equipped with Pallet Changers and other automation solutions. This integration allows them to function as part of a Flexible Manufacturing Cell (FMC) or Flexible Manufacturing System (FMS), effectively addressing a diverse range of machining requirements.

How Does a CNC Milling Machine Work?

In a CNC milling machine or machining center, the fundamental concept involves securing the workpiece on the machine table. This can be achieved by clamping it directly onto the table or by using a vice or fixture to hold it in place.

Once the part is secured, the spindle, which houses the cutting tool, is positioned either vertically or horizontally. This setup enables the tool to access various X-Y-Z coordinates on the workpiece, initiating the cutting and shaping processes.

During this operation, the workpiece may remain stationary, be mounted, or be moved linearly by the table in relation to the spindle and cutting tool. This movement facilitates the precise removal of material to achieve the desired shape of the machined part. CNC milling machines can be categorized as either horizontal or vertical in orientation.

How to Use a CNC Milling Machine in 5 Steps

Then comes the major question which is how to use a CNC mill. This step-by-step guide will help you with your question:

Figuring out the CNC Mill

First of all, follow a series of key steps for both accuracy and efficiency in the machining process. Spend time getting to know the control panel, spindle, tool holders, and work table of the CNC mill. Refer to the manufacturer’s manual to fully comprehend the unique features and capabilities of your specific machine.

Don’t forget to don the appropriate safety gear, such as goggles and gloves, and become well-versed in safety protocols to reduce the likelihood of accidents. Before moving on to the next stages of how to use a CNC mill, mastering safe and effective operation is imperative.

Do the Designing and Programming

The next step involves gearing up for the design and programming phase. Begin by employing CAD (Computer-Aided Design) software to create a detailed 2D or 3D model of the component you intend to produce. Once the design is complete, it must be transformed into a format compatible with the CNC mill, usually via CAM (Computer-Aided Manufacturing) software.

This software helps with generating the G-code, the language understood by CNC machines. To know how to use a CNC mill, tailor the G-code to suit the specific material and tooling you will be using, as this optimization will significantly impact both the process and the final products’ quality.

Set Up the CNC Mill

To get the CNC mill ready for operation, the first task is to secure the workpiece onto the machine’s worktable. Use clamps or vises to hold it firmly in place, preventing any unwanted movement during machining. After that, install the correct cutting tool into the spindle and tightly fasten it.

Next, enter the G-code into the CNC mill’s control system and perform a dry run without activating the cutting tool. This step is vital for verifying that the program operates smoothly and helps to avoid any potential collisions.

Start Performing the Machining Process

Next on how to use a CNC mill, it’s time to execute the machining process. Start the CNC mill and maintain a close watch on the operation. Pay careful attention to the feed rate, spindle speed, and coolant flow, as these parameters can greatly influence the quality of the machining and the longevity of the tool.

Be ready to pause or halt the machine if you detect any irregularities, such as unusual noises or vibrations, which may signal a problem. Regularly monitor the progress and dimensions of the workpiece to ensure it aligns with the desired specifications.

Once the machining process is complete, carefully remove the workpiece from the machine, taking care to avoid any sharp edges or burrs that may have formed during cutting. Inspect the finished part for accuracy and quality, using calipers or other measuring tools to confirm that it meets the required tolerances. If necessary, perform any additional finishing processes, such as sanding or deburring, to achieve the desired surface finish.

Maintenance and Troubleshooting

After successfully completing the machining process by following the how to use a CNC mill guide, focus on maintenance and troubleshooting to ensure the CNC mill remains in optimal working condition. Regular maintenance includes cleaning the machine, lubricating moving parts, and checking for wear on tools and components. Establish a routine maintenance schedule based on the manufacturer’s recommendations to prolong the life of the machine and prevent unexpected breakdowns.

In the event of issues arising during operation, such as inaccurate cuts or machine errors, review the G-code for any programming errors, and check the setup to ensure that the workpiece is properly secured and aligned. Inspect the cutting tools for damage or dullness, as these factors can significantly impact machining performance.

Conclusion

A CNC milling machine is a widely used device in many industries. These machines are available in both professional and hobbyist types. The how to use a CNC mill guide can help you to achieve the best results you’re expecting. At Maple CNC, not only can you purchase high-quality CNC machines, but also you can get a consultation from experts to show you the exact instructions you need.