You’ve just got a CNC router or maybe thinking about getting one? Anyway, to fully harness its capabilities, it’s essential to understand the pro CNC router parts and accessories that will help you to get the most out of your materials. This guide will explore the key components that will enhance your CNC router’s performance.

Pro CNC Router Parts and Components

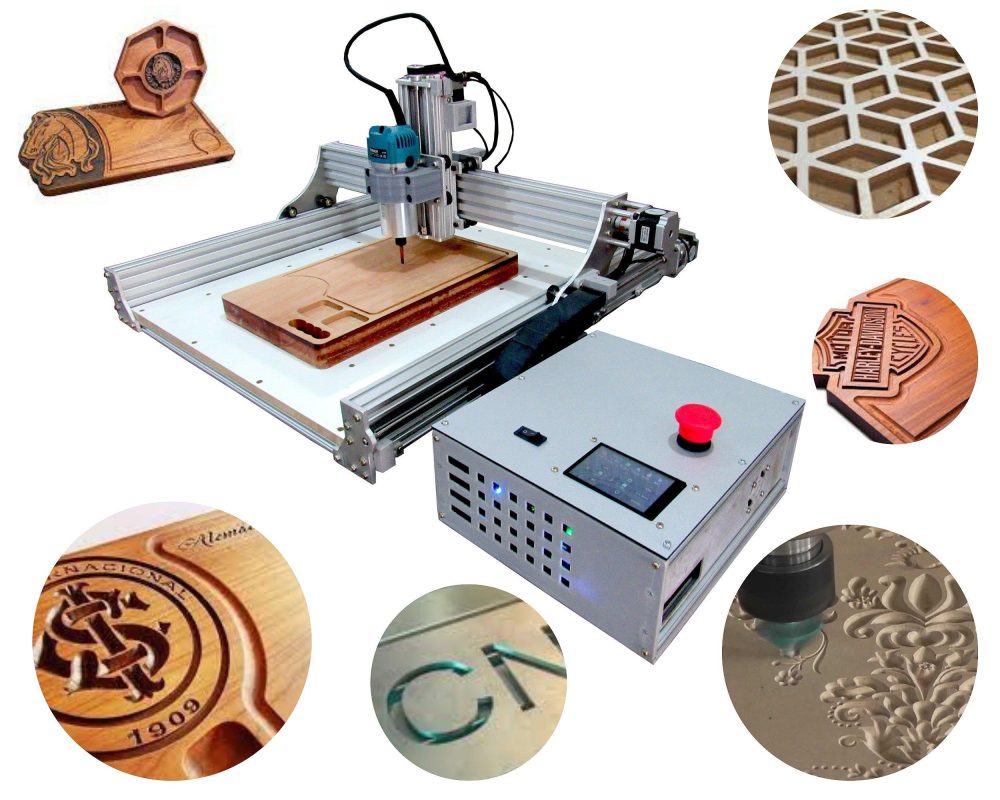

CNC routers are versatile machines that can be used for a variety of woodworking tasks, such as engraving, carving, and shaping. They are invaluable tools for prototyping and creating products like cabinets, signs, and musical instruments.

When purchasing a CNC router, consider prioritizing these specific components and machine parts:

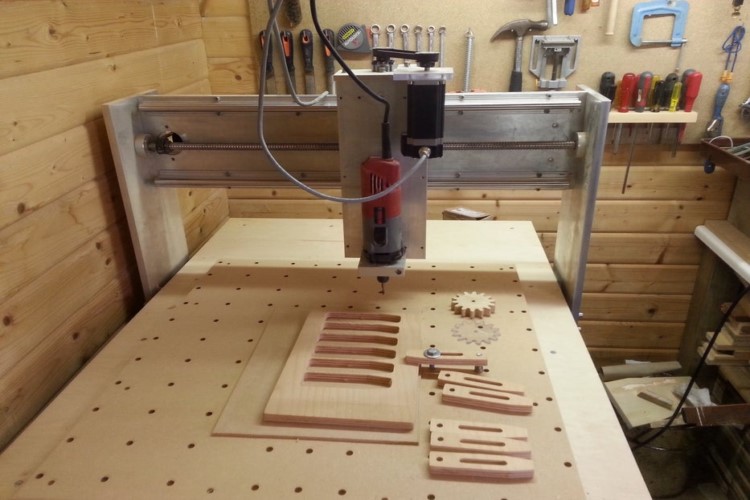

CNC Router Table

Tables, pro CNC router parts, vary widely in construction and workpiece holding systems. The most adaptable tables incorporate integrated T-slots, vacuum pulldown, or a combination of both to secure clamping of diverse workpieces in any position.

Aluminum extrusion tables are another popular choice, offering a compelling balance of stiffness, flexibility, and lightweight design.

For the DIY enthusiast, constructing a custom T-slot table using robust machined materials is entirely feasible. Such tables can be designed with slots on both sides of the axes to provide maximum versatility.

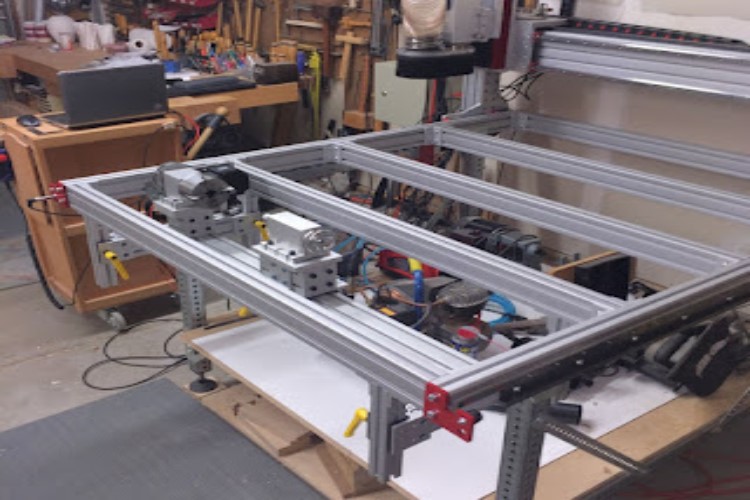

CNC Router Frame

The CNC router’s frame is its backbone because it provides the essential rigidity to support high-speed cutting operations. A flexible frame as a pro CNC router part can compromise precision to cause issues such as cross-bridge flexing, chatter, and axis displacement.

To ensure optimal performance, it’s crucial to select a CNC router with a sturdy frame capable of withstanding the dynamic forces involved in the cutting process.

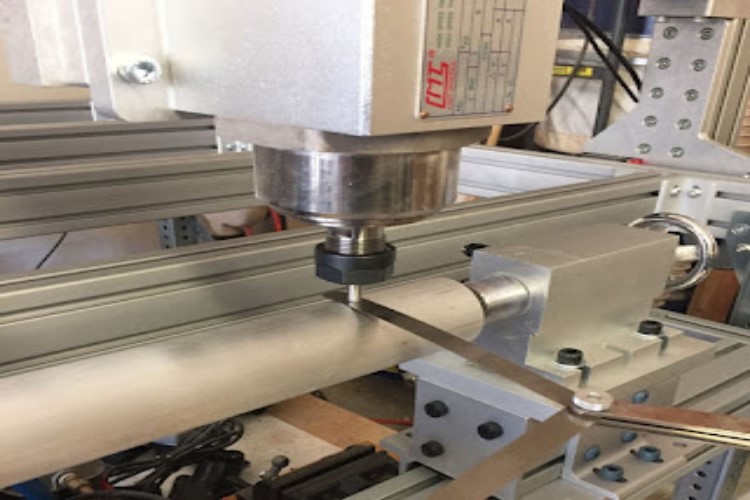

CNC Router Sliding Ways

The precision and quality of CNC router output hinges on the accuracy of its motion systems, including the sliding ways, frame, and lead screws.

Several types of these pro CNC router parts are employed in CNC routers. V-groove systems utilize ball bearings constrained within a track, often riding on a triangular extrusion or the edge of an angle iron. While these systems are the most affordable, they are susceptible to backlash and require frequent adjustment.

Round shaft systems, also using ball bearings, offer improved performance over V-groove systems. However, linear slides represent the pinnacle of sliding way technology, delivering the highest levels of precision and accuracy.

CNC Router Spindle

The spindle is a necessary and pro CNC router part of the CNC machine. Low-cost spindle designs often integrate the spindle directly into the motor shaft, relying on the motor’s bearings for support. This configuration can lead to premature wear and tear, particularly if the motor bearings aren’t sufficiently robust.

Spindle and motor bearings require regular maintenance to ensure optimal performance. Loose bearings can result in a wobbly cutter, compromising accuracy, while overly tight bearings can increase friction, excessive heat, and reduced efficiency.

CNC Router Controller

The CNC controller interprets G-code instructions and translates them into precise movements of the cutting tool. This intricate process involves generating electrical signals that direct the tool’s trajectory.

A diverse range of these pro CNC router parts are available, each with its unique capabilities. Options include standalone single-board controllers, single-board controllers with PC connectivity, and PC-based controllers equipped with motion control accessory boards.

CNC Axis Drive

The CNC router’s axis drive system is responsible for translating the rotary motion generated by stepper motors into linear movement along the X, Y, and Z axes. Entry-level machines often employ toothed belts or timing belts for this purpose, which, while less precise, can be remarkably durable with proper maintenance.

Higher-end machines typically utilize recirculating ball screws, offering superior accuracy and smoother motion. However, these systems demand meticulous care to mitigate wear and tear.

When selecting these pro CNC router parts, several key factors should be considered:

- The initial investment and ongoing maintenance expenses.

- The power and speed requirements of the motors.

- The system’s play or slack amount.

CNC Router Scanner

A CNC scanner can transform your CNC router into a powerful tool for reverse engineering which help you to replicate rare or discontinued products. A 2D optical scanner is sufficient for capturing the essential details of your target object.

For instance, to reproduce an intricately designed gasket, you can simply scan the original piece with the optical scanner. This process generates a digital representation, capturing the object’s dimensions, edges, lines, and shapes.

Once you have this digital blueprint, you can transmit it to your CNC controller, which will guide the router in creating an exact replica of the original gasket.

An optical scanner, this pro CNC router part, is an invaluable asset for CNC businesses specializing in the restoration, repair, or reproduction of limited-quantity parts.

CNC Router Dust Collector

A CNC machine is not just a tool; it’s an investment that requires care and maintenance to maximize its lifespan. As the machine diligently cuts through metal, wood, or plastic, it generates tiny particles that can pose significant risks. These airborne particles can obscure your view of the work, potentially leading to accidents.

Inhaling these particles can also have detrimental health effects, causing respiratory irritation and other health problems. A dust collector is an essential tool to mitigate these risks. By effectively capturing and containing these particles, this pro CNC router part ensures a clean, safe, and productive work environment.

CNC Tool Holder

CNC machines utilize a variety of cutting tools, including mills, drill bits, cutters, taps, saws, and engraving tools. To interface these tools with the spindle, a tool holder is essential.

The tool holder serves as the crucial connection between the cutting tool and the spindle for a secure and precise alignment. While firmly gripping the tool, some holders incorporate a “floating” mechanism to minimize wear and tear on the spindle, tool, and workpiece.

Like any mechanical component, tool holders are subject to wear and tear, which can compromise the CNC machine’s accuracy. Regular maintenance and timely repairs are vital to maintain optimal performance.

CNC Router Cutting Bits

For those who frequently drill with their CNC machine, having a surplus of router bits is a wise investment. Cutting bits, like any tool, are susceptible to wear and tear, especially when used intensively or on particularly tough materials.

A 10-piece starter bit set is a solid foundation, but consider acquiring additional sets of frequently used bits. This proactive approach can save you time and frustration, particularly if you reside in an area with limited access to local hardware stores and pro CNC router parts.

CNC Router Automatic Tool Changers

While simple CNC machines may suffice for basic tasks involving a single tool, more complex projects necessitate a variety of tools. Manually changing tools can be a time-consuming and inefficient process, especially for slow-production machines.

Advanced CNC machines are equipped with automatic tool changers (ATCs) that streamline the tool-switching process, eliminating the need for manual intervention. These ATCs can hold up to 10 different tools for seamless transitions between cutting operations during mass production.

By automating the tool-changing process, ATCs significantly enhance productivity and efficiency. Simply input the necessary commands into the computer, and the ATC will automatically select and install the required tool, ensuring a smooth and uninterrupted workflow.

Conclusion

In the first place, it’s important to understand the fundamental pro CNC router parts. We’ve explored the basics of CNC routers and highlighted key parts to consider. However, equally important is partnering with a reliable CNC part provider. Maple CNC offers a comprehensive solution for custom parts across various industries to provide the flexibility to meet your specific needs.