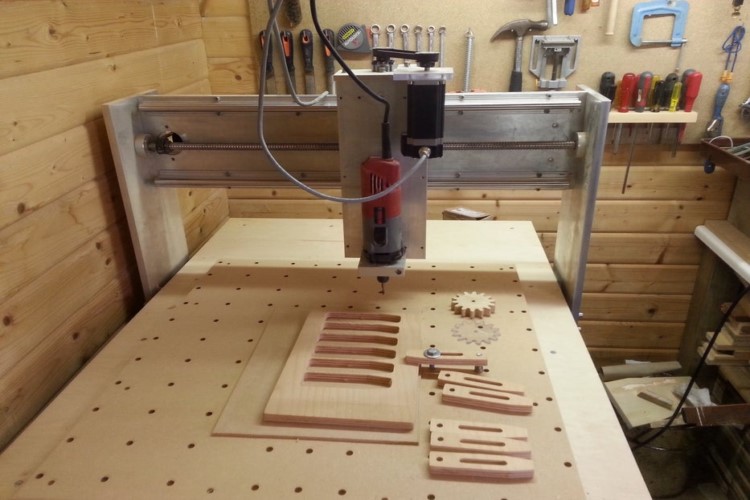

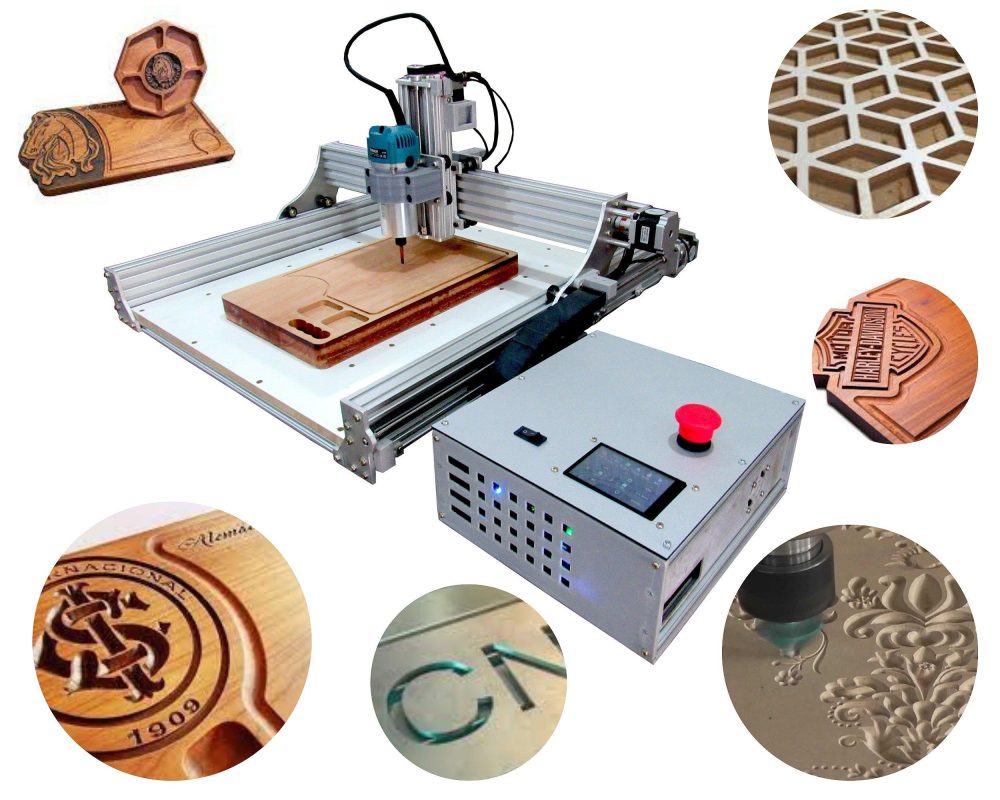

CNC router machines and handheld routers are essential tools in construction, woodworking, stone carving, and the aluminum door industry. For that reason, understanding the proper use of Rockler CNC bits is crucial for woodworkers, hobbyists, and professionals. With many router bit types available, choosing the right ones can be challenging.

What Types of Rockler CNC Router Bits Are There?

Cutting bits can be generally classified into two main types:

- Solid Carbide Tipped Router Bits, which feature a steel shank body and tungsten carbide-tipped cutting edges for enhanced durability during use.

- Solid Carbide Router Bits, are constructed entirely from Tungsten Carbide material.

We will explore each category in detail below to provide you with a clearer understanding.

Carbide Tipped Router Bits

Rockler CNC bits offer the other category of cutting bits which are Carbide tipped router bits designed for durability and precision, featuring a hardened carbide cutting edge that maintains sharpness longer than standard steel bits. Different types of this category are as follows:

Straight Router Bits

One of the most commonly used types of router bits is the straight one. They are designed to create straight cuts or slots in various materials for the formation of grooves or the hollowing out of areas. Available in a range of flute or cutting diameters, the most typical sizes range from 3/16″ to 1 1/2″.

Flush Trim Router Bits

Flush trim router bits are essential for anyone frequently working with wood veneer or plastic laminate. These bits feature a pilot bearing that matches the cutting radius of the bit for precise trimming of one material’s edge to align perfectly with another.

They are particularly useful for trimming veneered surfaces flush with a substrate or for creating multiple identical shapes using a pattern.

Rabbeting Router Bits

While a rabbet can be cut using a table saw with a Dado blade or a straight router bit, a specialized rabbet router bit from Rockler CNC bits is often the preferred choice for this task. This type of bit functions similarly to a dado but is specifically designed to cut along the edge of the workpiece.

The rabbet router bit rides along the edge of the material to remove excess material. These bits are typically equipped with a bearing at the top.

Raised Panel Bits

These router bits are primarily designed for creating decorative door panels and crafting various profiles on materials such as wood and MDF. They are ideal for adding intricate designs to your wood panels.

Edge Forming Router Bits

For those looking to create unique and decorative edges on wood pieces, edge-forming router bits from Rockler CNC bits are the perfect solution. There is a wide range of edge-forming router bits available, and the right choice will depend on your specific project needs.

Some of the most popular options include Round-Over bits, Cove routing bits, and Ogee bits, among others.

Solid Carbide Router Bits

These Rockler CNC bits are compatible with both handheld routers and CNC router tables which makes them incredibly useful for a wide range of tasks. Their ability to cut various shapes and styles means you can use them for almost any project you have in mind. Here are some types of solid carbide router bits:

Ball Nose Carving CNC Router Bits

Ideal for CNC and handheld routers, these bits are wonderful for creating detailed carvings and intricate designs tailored to your specifications. They are among the most adaptable solid carbide router bits you can add to your toolkit for achieving complex carvings. Available in sizes ranging from 1mm to 20mm, with various overall lengths to choose from, these bits are essential for any woodworking enthusiast.

Straight Cut Solid Carbide CNC Router Bits

True to their name, straight-cut router bits feature straight flutes for minimizing delamination and cracking on the top surface of MDF or wood projects. If your goal is to achieve a pristine finish on the upper layer of your workpiece, these bits are the ideal choice.

They provide a clean cut, ensuring that the surface remains smooth and free from imperfections. Go for this type of Rockler CNC bit if you want to create something aesthetically appealing.

Up-Cut Solid Carbide CNC Router Bits

Up-cut router bits are designed to pull chips upward during the cutting process. This upward force can sometimes lead to delamination on the top surface of the material. However, these bits are the most economical option available and are widely accessible.

They are suitable for bulk-cutting tasks as they excel at removing material quickly. If your project involves creating straight slots or grooves, up-cut bits are a practical choice, especially when speed and efficiency are your primary concerns.

Down-Cut Solid Carbide CNC Router Bits

Down-cut router bits direct the chips downward into the material. This design helps to maintain a clean top surface to reduce the risk of fraying or splintering, which is particularly beneficial when working with delicate materials. These bits are especially advantageous for projects that require a polished finish, as they leave the top layer smooth and intact.

Choose down-cut bits from Rockler CNC bits for applications where the material’s top surface is visible, such as in cabinetry or furniture making.

Single Flute Router Bits

These single flute router bits are essential tools for your toolbox, perfect for efficiently removing or scooping out large amounts of material from wood, aluminum, MDF, and more.

Materials Utilized in CNC Cutting Bits

Now that you have learned about the different types of cutting tools from Rockler, let’s explore some of the key materials employed in the production of cutting tools for CNC machines.

Carbon Steel

Carbon steel is an alloy that contains up to 1% carbon and as much as 1.6% manganese by weight. Tools crafted from carbon steel such as some Rockler CNC bits, are cost-effective and exhibit excellent machinability, and are suitable for low-speed CNC machining of softer metals such as aluminum, brass, and magnesium.

Ceramic

Resistance to corrosion and heat are the most important features of cutting tools made from ceramic. Their chemical stability ensures that they do not react with most metals used as workpieces. These tools are highly efficient for cutting and are particularly effective in high-speed semi-finishing and finishing processes for hard steels, cast iron, and superalloys.

High-Speed Steel (HSS)

High-speed steel is essentially carbon steel enhanced with additional elements like molybdenum, tungsten, chromium, cobalt, and vanadium. These alloying components impart exceptional heat and abrasion resistance, as well as increased durability.

HSS cutting tools are particularly well-suited for continuous high-speed cutting applications and can effectively process both ferrous and nonferrous metals.

Carbide

A type of composite material made from tungsten and carbon is called carbide. Cutting tools manufactured from carbide like Rockler CNC bits are known for their remarkable resistance to heat, corrosion, and wear. They significantly outlast steel-cutting tools, especially in demanding conditions.

Conclusion

Now that you have a clear understanding of the types of router bits and their application, you are well-equipped to go for your first routing project. Whether you’re using a newly purchased router table or a handheld router, you can confidently select the appropriate Rockler CNC bit from Maple CNC for your needs.