In a universe where creativity knows no limits, CNC plotters have quietly become the champions of the design and manufacturing world. These incredible machines serve as a bridge between our digital dreams and the physical world, enabling artists, engineers, and makers to transform their ideas into reality with remarkable accuracy. let’s get into this article to see what is CNC plotter and check how this machine can change the game in creative expression.

What Is a CNC Plotter and How Does It Function?

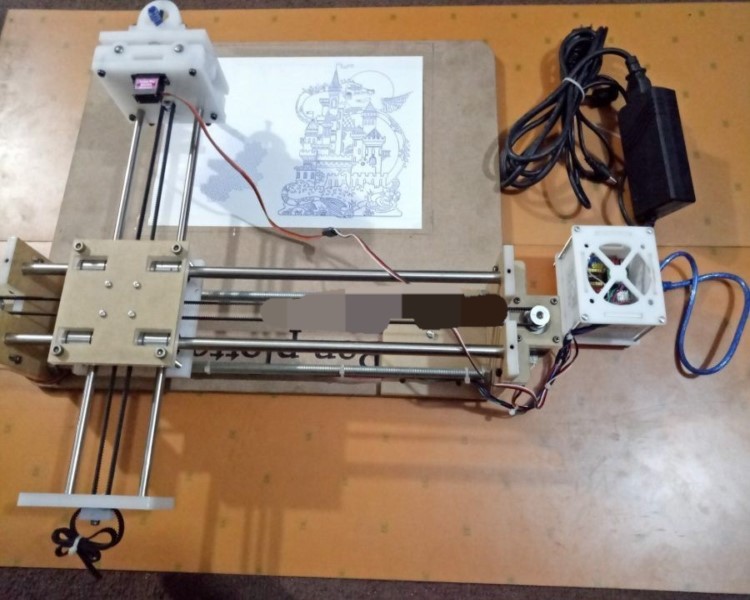

A CNC plotter is a fantastic little machine that brings your digital designs to reality. It’s like a super precise artist that uses a computer to guide it. It moves a pen or other drawing tool across a surface and turns your ideas into beautiful physical creations.

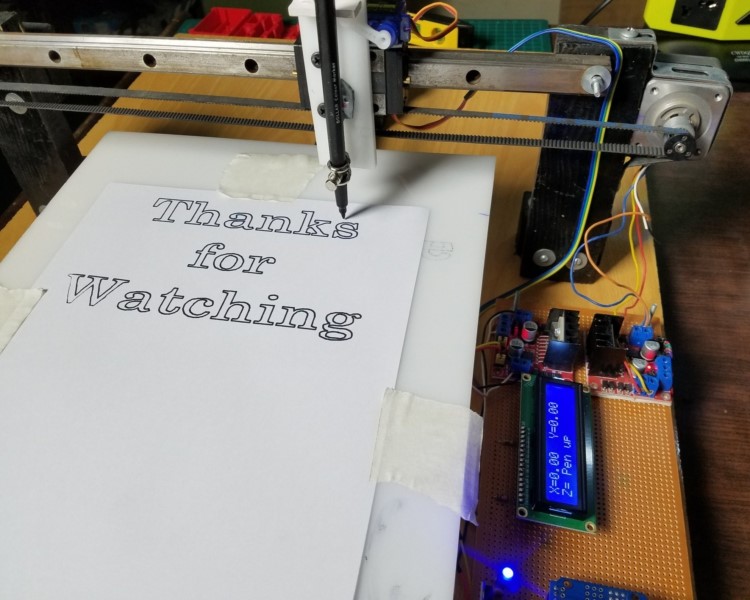

What is CNC plotter at its core? A CNC plotter works using computer numerical control (CNC). This means it follows a set of instructions, usually written in a special code called G-code, to move its parts with incredible accuracy which leads to the creation of intricate designs and patterns that are just spot on every time.

So, how does it all work? Well, the plotter has a clever setup of motors, belts, and a platform that holds the surface you want to draw on. The software takes your digital design and breaks it down into coordinates, which tell the drawing tool how to move along the X and Y axes.

As the tool glides across the surface, it uses ink or other materials to create the image or text you thought up. The best part is that the entire process is automated, so you can sit back and watch as your complex designs come to reality with very little effort on your part.

The Difference Between CNC Router and CNC Plotter

What is CNC plotter difference with a CNC router? CNC routers and CNC plotters are both impressive machines that use computer numerical control, but they perform different purposes and work in their own unique ways.

CNC Router

CNC routers are designed to cut, carve, and shape a wide range of materials, including wood, plastic, metal, and composites.

With tools like end mills and drills, they can perform tasks such as milling and engraving, allowing for the creation of beautiful, complicated three-dimensional designs. The features they have make them super practical in industries like woodworking, cabinetry, and manufacturing, where crafting furniture, decorative pieces, and prototypes is key. Thanks to their three-axis movement system, CNC routers can tackle complex cuts and shapes by removing material from a solid block to achieve the desired look.

CNC Plotter

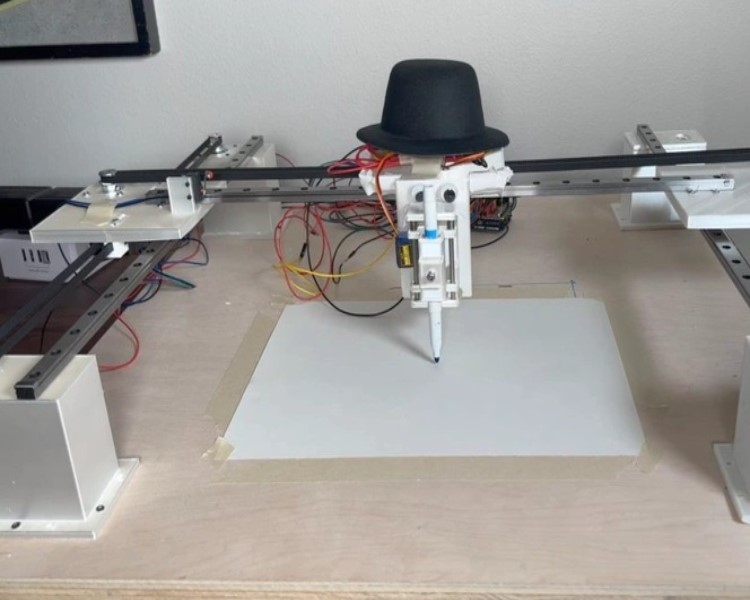

On the other hand, what is CNC plotter? CNC plotters are the artists of the machines. They focus on drawing and printing graphics, designs, and text on surfaces, primarily creating two-dimensional outputs. Instead of cutting tools, they use pens, markers, or other drawing instruments to bring images and text to life.

Some advanced models can even cut through thin materials like vinyl. You’ll often find CNC plotters in graphic design, signage, and textile industries, making them perfect for producing banners, posters, and detailed designs on paper or vinyl. While they also operate on a three-axis system, their main job is to move the drawing tool across a surface rather than removing material.

Applications of CNC Plotter Machines

What is CNC plotter application? Plotter machines have truly become essential tools in a variety of industries, thanks to their incredible precision and versatility. In fields like architecture and engineering, these machines are key players in creating highly accurate technical drawings, maps, and renderings. This level of detail is vital for effective project planning and execution.

With the ability to produce large-format prints, architects and engineers can really bring their designs to life, ensuring that every little detail is carefully considered.

But it doesn’t stop there! In the world of cartography and Geographic Information Systems (GIS), CNC plotters shine by generating high-quality maps with outstanding accuracy. According to the spectacular features of CNC plotters, they are absolutely a must-have for professionals who need exact geographical data representation.

More CNC Plotter Applications

What is CNC plotter application in other industries such as the textile industry? CNC plotter machines are also making waves in the fashion and textile design industries. They can print complex designs and cut fabrics all at once, which not only streamlines the production process but also sparks creativity in design. Their large-scale printing capabilities are especially valuable in the clothing sector, where efficiency and authenticity are key.

In manufacturing and prototyping, CNC plotters are a fantastic resource for testing product concepts before diving into full-scale production. This allows manufacturers to visualize and refine their designs, saving both time and resources while ensuring that the final product meets high-quality standards.

How Noisy Is a CNC Plotter?

After all that we explained above, one should ask, what is CNC plotter noise level? The noise level of a CNC plotter can fluctuate based on various factors, such as the machine’s type, size, the materials being used, and its components like motors and bearings.

Generally speaking, CNC plotters tend to be quieter than traditional CNC milling machines since they often utilize less powerful motors and operate at lower speeds. On average, you can expect the noise level of a CNC plotter to fall between 50 to 70 decibels (dB). To put that into perspective, a normal conversation is around 60 dB, while a vacuum cleaner typically reaches about 70 dB.

If noise is something you’re worried about, there are a few strategies you can consider to keep things peaceful. First, think about the location of your plotter; placing it in a separate room or designated area can significantly reduce noise disturbance.

Incorporating soundproofing materials around your workspace can help dampen the sound. Regular maintenance is also key, as it ensures that your machine runs smoothly and quietly. If you have specific models in mind, checking the manufacturer’s specifications or user reviews can give you a clearer picture of their noise levels.

How Much Does a CNC Plotter Cost?

If you’re thinking about getting a CNC plotter in Canada, you need to know what is CNC plotter’s price tag. You’ll find that the prices can really vary depending on a few things like the brand, size, features, and what the machine can do. On the lower end, you might find entry-level models starting around CAD 1,000, while high-end, industrial-grade machines can set you back CAD 10,000 or even more.

If you’re eyeing something more specialized or larger, be prepared for those prices to climb even higher. Don’t forget to factor in some extra costs too, like software, maintenance, and any accessories you might need. After all, getting in touch with local suppliers as well as browsing online marketplaces can help you get a better idea of the prices out there.

Conclusion

To wrap things up about what is CNC plotter, they are far more than mere machines; they are dynamic tools that fuel creativity and innovation across a multitude of fields. From crafting detailed architectural designs to optimizing textile production, these devices have consistently demonstrated their value. Before buying a machine, it’s essential to clarify your objectives and select one that aligns with your requirements. If you’re uncertain about which CNC machine to choose, it’s advisable to consult with experts in the field to avoid potential losses.