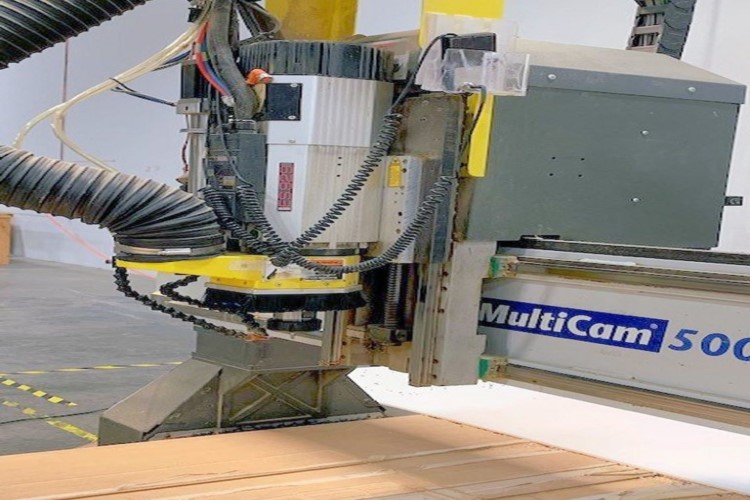

Multicam CNC machines are pretty awesome when it comes to precision manufacturing. They’re versatile, reliable, and can handle a whole bunch of materials and projects without breaking a sweat. But what really makes these machines tick is the impressive array of parts that work together for peak performance.

In this article, we’ll take a closer look at the essential Multicam CNC parts and cool accessories that make these machines special. Knowing these parts is key to getting great results and unlocking your machine’s full potential.

About Multicam CNC Machine

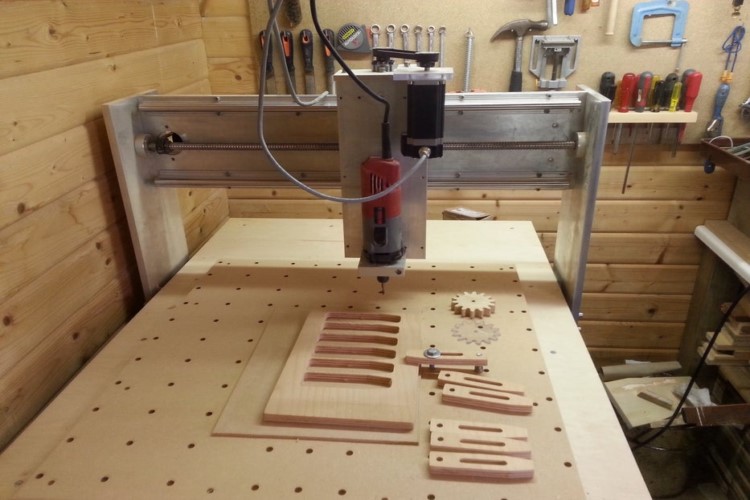

Multicam CNC machines are specially designed for top-notch precision and flexibility, working wonders with a variety of materials like wood, metal, plastics, and composites.

Take the Multicam 3000 Series, for instance; it’s built tough with a solid steel frame and comes with a cutting-edge laser or router cutting bits, letting users create detailed designs with super tight tolerances of just ±0.01 mm. This series rocks a cool Dynamic Profile technology that allows for on-the-fly adjustments while cutting, which not only boosts productivity but also cuts down on waste.

Another impressive aspect of the Multicam machines is the user-friendly interface. The MultiCam Control Software offers a sleek touch-screen experience that makes operating the machine a breeze. It supports a bunch of file formats, like DXF and DWG, and works smoothly with popular CAD/CAM programs.

Plus, you can customize the machines with various heads, like oscillating and tangential knives, for different needs.

With options for automatic tool changers and advanced material handling systems, Multicam CNC parts really amp up productivity for folks in manufacturing, woodworking, and fabrication, cementing their spot as a frontrunner in the world of advanced CNC tech.

A Deep Dive into Multicam CNC Parts

Multicam CNC machines are seriously sophisticated beasts, and they need a whole lot of parts to sing and dance like they’re supposed to. Let’s break down the key players in this CNC orchestra:

Core Components

Spindles: Spindles are the high-powered engines of the machine. These whirlwind tools are the heart and soul of the operation, responsible for carving out and shaping materials with surgical precision. You’ll find spindles designed for everything from smoothly slicing through wood to aggressively chewing through metals.

Controllers: These Multicam CNC parts are the masterminds behind the scenes. They orchestrate the movement of the machine’s axes, ensuring spot-on accuracy and flawless positioning. These controllers are packed with cutting-edge technology, allowing for incredibly complex and precise cuts.

Motors: The driving of the machine’s axes is done by important Multicam CNC parts which are the motors. They need to be strong and reliable to handle the demands of high-speed cutting.

Axes: For the cutting head to glide smoothly and precisely in three dimensions (X, Y, and Z), the machine needs parts called axes. Imagine them as super-smooth tracks guiding the cutting head on its journey.

Vacuum Tables: These CNC parts are essential for holding down materials during the cutting process. Without them, your workpiece would fly all over the place, leading to messy and inaccurate cuts. These tables suck down the material, keeping it firmly in place like a vice grip.

Dust Collection Systems: The Multicam machine and the operator will be kept safe for a long time with a dust collection system. Dust collection systems suck up all the dust and debris created during the cutting process, keeping the workspace clean and healthy.

Cutting Tools

Router Bits: Router bits are one of the most important Multicam CNC parts. Available in a mind-boggling variety of shapes and sizes, there’s a router bit for every cutting challenge imaginable. From sharp v-bits for intricate designs to heavy-duty downcut spirals for deep cuts, the options are endless.

Saw Blades: For tackling thicker materials or making clean, straight cuts, saw blades come into action. They can be used for wood or any other material.

Knife Cutters: These are ideal for gently cutting softer materials like foam or fabric. They’re like a hot knife through butter! You can make quick work of delicate materials using them.

Engraving Bits: These marvel Multicam CNC parts are used to create stunning intricate designs and patterns. They’re tiny but sharp and strong enough to work on so many materials such as wood, aluminum, foam, and more.

Accessories

Tool Changers: These automatic tool changers are important for more productivity, especially in industrial settings. They quickly and effortlessly switch between different cutting tools, saving you valuable time and keeping the cutting process flowing smoothly.

Probes: Probes are high-tech Multicam CNC parts used for precisely measuring and aligning materials, ensuring spot-on accuracy in every cut. They have a super-accurate measuring tape built right into the machine.

Coolant Systems: These systems apply coolant to the cutting tool and workpiece, to keep things cool and prevent overheating. This leads to longer tool life and better cutting performance.

Fixtures: To hold things in place you need fixtures as they can hold your workpiece securely in place during the cutting process, to ensure accuracy and repeatability every single time.

Software: Multicam’s proprietary software is the brains of the operation. It’s used to design, program, and control the entire CNC machine. CNC software is a true powerhouse of productivity.

How to Assemble Multicam CNC Parts in 5 Steps

Whether you’re purchasing Multicam CNC parts separately or as a complete kit, the general assembly instructions remain the same. Here are 5 main steps for putting Multicam parts together according to experts:

Foundation and Framework

Experts begin by assembling the sturdy base frame to ensure it’s perfectly level and square. This foundation is crucial for the machine’s stability and overall accuracy. They meticulously align and secure all components, following precise measurements and torque specifications outlined in the assembly manual.

Axis Integration

Next, they integrate the X, Y, and Z axes, the backbone of the machine’s movement. This involves carefully aligning and mounting linear rails and bearings for smooth and precise motion along each axis. Any misalignment at this stage can significantly impact the machine’s accuracy and cutting performance.

Spindle Installation

The spindle, the important Multicam CNC part, is then mounted onto the Z-axis. Experts pay close attention to alignment and secure the spindle with utmost care. In this step, spindles must be perfectly centered and balanced. They also connect power cables, coolant lines, and other necessary connections.

Control System Integration

The control system, the machine’s brain, is thoroughly integrated. This involves connecting cables for power, motor control, and other essential functions. In this step, you should carefully configure the control system parameters to make smooth communication between the controller and all machine components.

Testing and Calibration

Finally, experts perform a series of rigorous tests to verify proper functionality. This includes moving the axes, testing the spindle’s operation, and checking vacuum table performance. They then calibrate the machine’s axes, fine-tuning settings to achieve optimal accuracy and precision. This rigorous calibration process is crucial for ensuring the machine delivers consistent and high-quality results.

Conclusion

The Multicam CNC machine is made up of a bunch of essential parts and accessories that work together to keep it running smoothly. Key components include the frame, spindle, and cutting tools, to name a few. Pros follow a careful assembly process to make sure everything fits together just right since precision is key for high-quality results. If you’re on the hunt for Multicam CNC parts, check out Maple CNC for expert advice and options.