CNC routing technology is making waves across a variety of industries as this amazing tool empowers both talented artisans and innovative engineers to turn their imaginative visions into reality. So, If you’re a seasoned experienced or just dipping your toes into this field, discovering the possibilities of CNC router projects in this article will surely inspire you to create masterpiece collections.

Applications of CNC Routing

In today’s modern world, a lot of industries benefit from CNC routing for many compelling reasons. Here are the major sectors that rely on these machines for their production:

The Industry of Woodworking

Woodworking relies heavily on CNC routing because it allows for precise and complicated cuts, detailed designs, and various types of joinery, like dovetails and mortise-and-tenon joints. As you know, the woodworking industry itself includes many sub-industries such as furniture, cabinetry, and music instruments and all of them require CNC router projects to get their job done perfectly.

In furniture making, for example, this technology helps artisans create both modern and traditional pieces with complicated designs and perfect fits, ensuring that every item is of high quality and looks great.

Similarly, in cabinetry, CNC routing is utilized to put together cabinets and shelves with intricate patterns and exact measurements to stimulate both their functionality and visual appeal.

CNC routing is fundamental in crafting musical instruments, as it shapes wooden parts for guitars, violins, and more. In these CNC router projects, exactitude is key, as it directly affects the sound quality and overall performance of the instruments.

Engraving and Signage Sector

The signage industry has made great strides thanks to the introduction of CNC routing technology. This innovation enables precise cutting of letters and shapes from a wide range of materials to create high-quality outdoor and indoor signs. As a result, we can now create durable signage from wood, plastic, and metal.

CNC router projects for engraving have broadened to include personalized options for many items. In other words, this custom engraving service meets corporate demands by offering unique and meaningful engravings for gifts, awards, nameplates, and memorabilia, adding a personal touch to a variety of products.

Automotive and Aerospace Industry

Other industries that utilize CNC router machines are automotive and aerospace in which this innovation plays a key role when it comes to prototyping, fabricating parts, and creating custom components.

Precision, versatility, and applicability on a wide range of materials are the most important features of good CNC routers. These features are of importance for quickly producing parts for testing and design validation, as well as for manufacturing unique components that adhere to strict industry standards. That’s why CNC router projects are an integral part of automotive and aerospace engineering worldwide.

Marine Sector

The marine industry heavily depends on CNC routing for the creation of various boat components, including hull parts, decking, and interior cabinetry, as well as custom dash panels and decorative elements. The high accuracy of CNC routers guarantees a perfect fit for each component which improves both functionality and aesthetics.

Key applications of CNC router projects encompass boat building, where hull components and interior features are meticulously cut and shaped, and the design and manufacture of bespoke control panels tailored for boats and yachts.

Decorative and Architectural Applications

Architectural firms and interior designers are increasingly turning to CNC routing to transform their creative ideas into reality. This technology opens up a world of possibilities that allow for the creation of everything such as decorative panels, bespoke furniture, and unique architectural features.

For instance, you can utilize CNC router projects to craft intricate designs for both indoor and outdoor decorative panels and screens to add a touch of elegance to any space. With CNC routing, you can produce custom architectural elements, such as distinctive moldings, facades, and structural components, and give the buildings a one-of-a-kind character.

Research and Education

CNC routing is employed by educational institutions and research centers to instruct manufacturing methods and carry out experiments. As a student or researcher, for fostering learning and innovation, CNC router projects allow you to design and produce accurate models and components for a range of plans.

Suitable Materials for CNC Routing

The success of any CNC routing project fundamentally relies on choosing the right material. But what materials are well-suited for CNC routing? Let’s find out the answer below:

Wood-Based Materials

Wood is a popular choice among both hobbyists and professionals due to its natural charm and ease of manipulation. You can use CNC routers to intricately carve, sculpt, and engrave wood to transform raw timber into stunning creations.

Hardwoods like oak, maple, and walnut are perfect and highly valued for furniture and decorative pieces because of their strength and beautiful grain patterns. On the other hand, softwoods such as pine and cedar are easier to work with, so they enable you to do detailed carvings without excessive wear on tools.

Plywood and MDF (Medium Density Fiberboard) are also excellent options for CNC router projects as they provide a consistent and stable surface that is crucial for precision parts and templates.

Plastic Materials

Plastics are another favored choice for CNC routing. Their applications range from prototypes to finished products, with possibilities that seem endless.

From a wide range of plastic materials, acrylic is particularly notable for its clarity and smooth finish. PVC (Polyvinyl Chloride) is a robust and chemical-resistant option, perfect for industrial components. Meanwhile, ABS (Acrylonitrile Butadiene Styrene) is recognized for its durability, often used for functional parts and enclosures.

Composite Materials

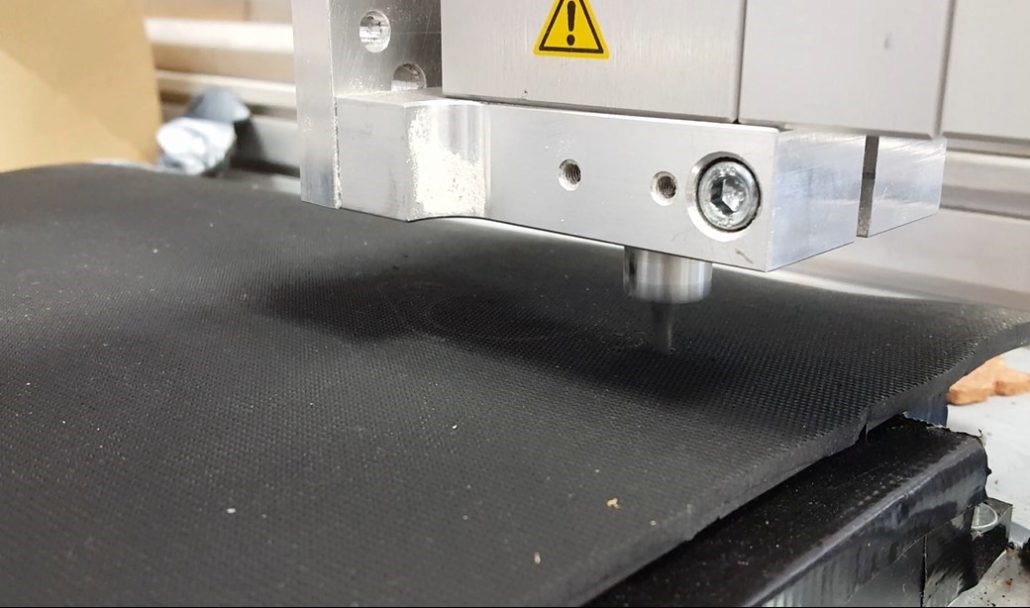

Composites like carbon fiber and fiberglass offer exceptional strength while remaining lightweight during CNC router projects. That’s why they’re ideal for high-performance applications in industries such as aerospace, automotive, and sports equipment.

Non-Ferrous Metals

Non-ferrous metals broaden CNC routers’ range of applications beyond wood and plastics! For instance, aluminum strikes a balance between lightness and strength which is very suitable for parts that require both qualities. Brass and copper, with their unique visual appeal, are commonly used in decorative arts and electrical components.

Foams and Modeling Materials

Modeling materials such as EVA foam and urethane can be easily shaped. So they can be ideal for CNC router projects for facilitating quick design development and modification. You can use these materials to create prototypes, architectural models, and theatrical props using a CNC router machine.

Other Materials

CNC routers are greatly versatile because you can use them to release your art on more than just wood or plastic. Rubber, cork, Corian, and similar solid surfaces, ceramic tiles, stone, and marbles are among the other materials that you can work with if you have a CNC router.

Conclusion

To wrap up, are you eager to innovate and create? Invest in a CNC router and start your CNC router projects. No matter what materials you tend to work with; be it wood, plastic, stone, aluminum, or rubber, CNC routers can do magic on them! Whether you’re a carpenter, an engineer, or a simple hobbyist, a CNC router is what you look for to expand the horizons of what can be accomplished with CNC routing.

If you’re excited to move your career to the next level, don’t forget to first consult with the experts in this technology to get the best option suited for you.