CNC software plays a crucial role in programming automated manufacturing tools, providing essential instructions for machining operations. It directs CNC machines on how to transform raw materials into finished parts while enabling virtual part creation, simulating and optimizing cutting processes, and automatically generating efficient G-code toolpaths. With the right homemade CNC software, manufacturers can enhance precision, efficiency, and automation in their machining tasks.

Understanding CNC Software

CNC software transforms drawings or models into precise machine instructions, effectively directing the movement and operations of CNC machines. Homemade CNC software empowers manufacturers to craft complex designs, generate toolpaths, simulate machining processes, and refine production workflows.

In general, four primary types of software come into play which are CAD, CAM, Control Software, and Simulation Software.

CAD is responsible for producing 2D, 2.5D, or 3D designs, effectively replacing traditional manual drafting by engineers and elevating the level of automation in the design process.

CAM software is tasked with preparing toolpaths and translating designs into G-code, a language that machines can interpret.

Control Software interprets G-code and sends signals to control stepper motor drives, essentially instructing the CNC machine on its actions.

Simulation Software predicts potential errors that may arise during the machining process by analyzing G-cod.

The Significance of Homemade CNC Software

The significance of homemade CNC software in manufacturing cannot be overstated. By facilitating a flexible, automated, and optimized manufacturing process, CNC software offers advantages that manual methods cannot match. Below are several key reasons highlighting the importance of CNC software:

Automation and Efficiency

The manufacturing landscape has been transformed by CNC software, which automates processes and significantly reduces the need for human intervention. This automation not only enhances efficiency but also allows CNC machines to operate continuously, thereby minimizing downtime and maximizing overall productivity.

Flexibility and Customization

One of the standout features of homemade CNC software is its ability to provide manufacturers with remarkable flexibility. Machines can be reprogrammed swiftly for various tasks for efficient production of customized products that meet specific customer needs.

Quality Control

Combining robust quality control mechanisms, CNC software ensures that the machining process adheres to specified tolerances. With features like real-time monitoring and feedback, the likelihood of errors and defects in the final product is greatly diminished.

Time and Cost Savings

Homemade CNC software significantly cuts down the time needed to produce components due to its ability to streamline the manufacturing process. The elimination of manual setups and adjustments leads to quicker production cycles, while also reducing material waste, ultimately resulting in substantial cost savings over time.

Precision and Accuracy

Achieving high precision and accuracy in machining operations is made possible through CNC software. It can convert design specifications into precise machine instructions and guarantee that the final products consistently meet the desired specs.

Complex Machining Operations

Homemade CNC software empowers manufacturers to undertake complex machining tasks that would be challenging or unfeasible to execute manually. It facilitates the creation of intricate designs, complex geometries, and precise contours, thereby broadening the scope for producing detailed components.

How CNC Software Function

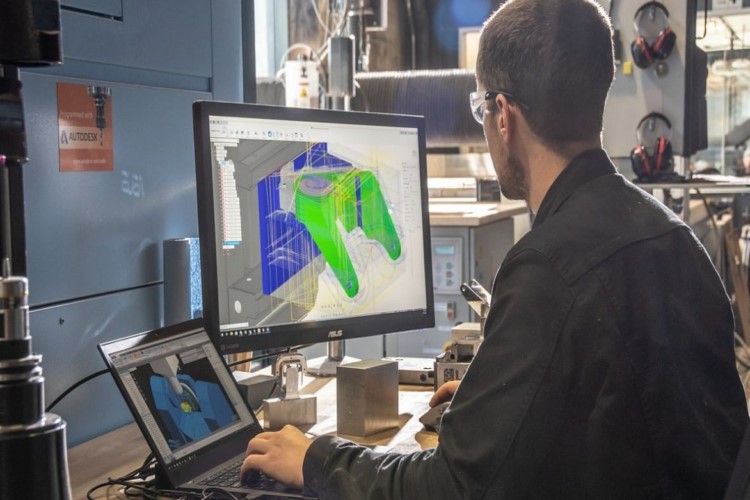

CNC software is the essential “brain” of the machining operation that transforms a CAD model into actionable motion and tool commands that enable the physical creation of a part. Here’s a concise overview of how homemade CNC software operates:

Making Initial Models

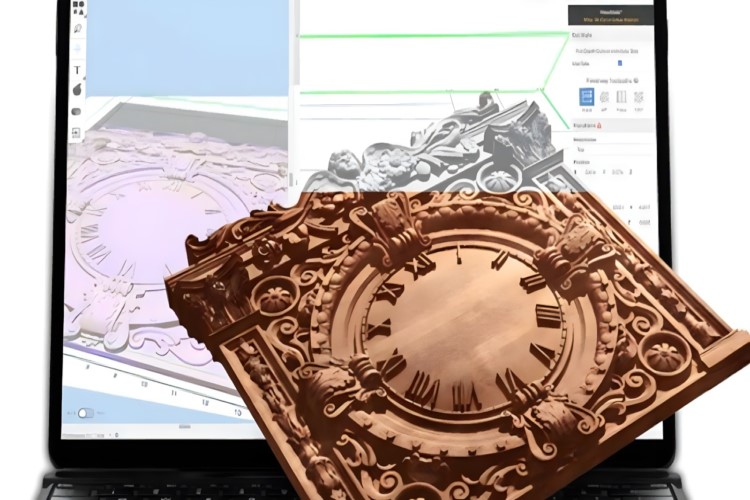

Initially, a model is crafted using either 2D drawings or 3D modeling software, with CAD software being the typical choice for this task. The CAD model outlines the geometry, dimensions, tolerances, and other critical specifications of the part.

While 2D models provide simple representations of parts to be cut, they are particularly useful for components that require uniform cutting heights. In contrast, 3D modeling offers advantages such as the ability to visualize assemblies and manage varying cut depths, allowing for the creation of more complex designs.

Producing Toolpaths

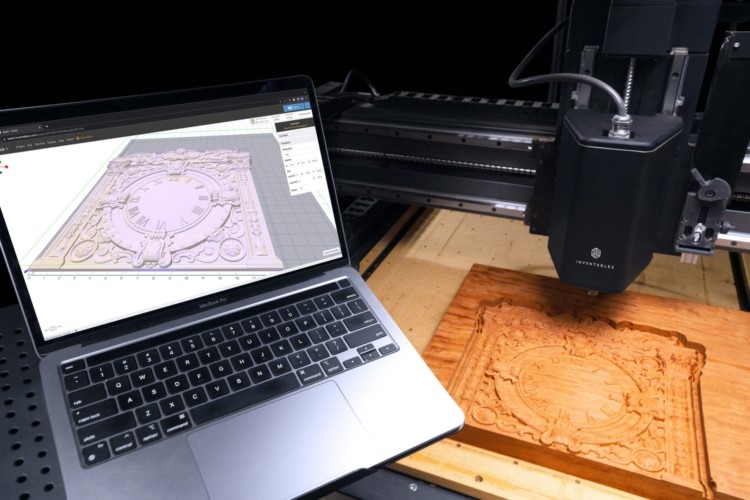

Next, the CAM software steps in to evaluate the model and produce toolpaths which are the designated routes that the cutter will follow during machining.

These toolpaths produced from homemade CNC software are meticulously optimized to reduce machining time, maintain dimensional precision, prevent collisions, and align with the machine’s capabilities. Factors such as cutter size, spindle speeds, and feed rates are all taken into account during this process.

Translating Toolpaths into G-code

The generated toolpaths are then translated into G-code, a programming language that conveys coordinates and commands to the machine, instructing its motors on how to move. G-code includes various commands that direct the machine, such as positioning the cutter at specific X, Y, and Z coordinates, activating the spindle at designated RPMs, adjusting the feed rate, and turning on the coolant.

Raw Materials Transformation into Final Parts

Finally, the CNC machine processes the G-code sequentially, guiding the tool along the predetermined paths to transform raw material into the finished part.

It’s important to highlight that while it’s technically possible to begin cutting the model at this stage, running a simulation beforehand is highly advisable. Once everything is confirmed, the actual cutting process can commence.

Key Considerations for Selecting the Right Homemade CNC Software

Choosing the appropriate CNC software is essential for enhancing both productivity and profitability in manufacturing. Thoughtfully evaluate the following aspects to ensure that the software you select aligns perfectly with your business requirements.

Supported CNC Techniques

Before purchasing a CNC software package, confirm that it can handle all necessary operations for part creation. Not every homemade CNC software solution accommodates a wide range of CNC techniques, including milling, laser cutting, and plasma operations. Get software that specifically supports the CNC methods essential for your manufacturing processes.

Budget Considerations

Many CAD packages come with a hefty price tag. That’s why doing thorough research is imperative before making a purchase. Remember, a higher price doesn’t always equate to superior quality, so focus on the features that are truly necessary for your operations. Newer homemade CNC software versions typically offer improved performance, so consider testing a free version before committing to a purchase.

User’s Technical Proficiency

The technical expertise of the user is another important factor in the software selection process. For those just starting out, simpler tools are advisable to build a solid foundation before advancing to more complex CNC software options.

Integration with Other Software

When selecting CNC software, carefully assess its compatibility with other systems. This can significantly streamline the process of preparing and transferring files for manufacturing. Choose software that not only performs well on its own but also integrates seamlessly with other tools in your workflow.

Accepted File Formats

CNC operations utilize various file types, including STEP, STL, IGES, DXF, X3D, and Parasolid, among others. The CAD homemade CNC software you use will generally dictate the file formats available. If your chosen software lacks compatibility with multiple file types, both for import and export, you may encounter huge challenges.

User-Friendliness

Seek out software with an intuitive interface and straightforward workflows for you and your team to learn and program efficiently. However, don’t compromise on functionality for the sake of simplicity. The ability to simulate and verify toolpaths is invaluable, so prioritize software that offers realistic material removal simulations.

Conclusion

Homemade CNC software is an invaluable tool in the manufacturing sector, specifically crafted to manage machine tools. Acting as the operational intelligence, it converts intricate design files into actionable commands for the machines. Selecting the right CNC software from reliable resources can greatly enhance productivity in machining, lower expenses, and optimize production processes.