A commonly used machine, Computer Numerical Control (CNC), whether industrial or homemade, helps to make many durable goods like aircraft, artificial joints, and cars. Homemade CNC cutter is one of the many categories of CNC machines which itself, comes in different types, sizes, and shapes. Each CNC cutter is suitable for a specific application. Understanding the types of CNC cutters will help you to select the one that better suits your project.

What Is CNC Machining with Homemade CNC Cutters

CNC machining, or Computer Numerical Control machining, is a sophisticated automated process that shapes objects by systematically removing material from a workpiece until the intended form is done. This technique relies on advanced software to dictate the movements and functions of the machines involved.

The operation of these machines is guided by algorithms crafted by designers, which provide detailed instructions on the movement of machine tools and the management of various secondary processes.

As a result, homemade CNC cutters offer exceptional flexibility, effectiveness, and perfection, for machinists to produce a wide range of items, from tiny electronic components to massive aircraft and aerospace parts.

Types of CNC Cutters

CNC cutters come in a variety of sizes and capabilities, from compact mills and lathes found in small machine shops and vocational schools to large, powerful systems equipped with multiple tools that operate across three, four, and even five axes. Let’s explore more about them here:

CNC Milling Machine

CNC mills rank among the most widely utilized CNC cutters, serving mainly for tasks such as milling, drilling, and cutting.

These machines interpret and transform designated sequences of letters and numbers, referred to as G-code, to guide the spindle along various routes and paths. Once the workpiece is secured within the milling machine, the computer takes control of the operation.

There are several common varieties of CNC milling machines, including hand, plain, universal, and omniversal models. They are equipped with capabilities for tapping, drilling, turning, and face milling, enabling them to work with tough metals. While the majority of these homemade CNC cutters operate on three axes, more sophisticated versions can support additional axes for enhanced functionality.

CNC Plasma Cutters

CNC plasma cutting machines utilize an electrical discharge arc, such as a plasma torch, to achieve precise cuts by ionizing the air and melting the material at the point of contact.

Due to their reliance on an electric discharge mechanism, these plasma cutters are limited to working with electrically conductive materials. Industries such as automobile manufacturing, automotive repair, shipbuilding, fabrication, and salvage and scrapping frequently employ CNC plasma cutters for their operations.

CNC Lathe Cutters

CNC lathe machines differ from CNC mills in that they excel with cylindrical, conical, or flat products. These cutters, either industrial or homemade CNC cutters, operate by rotating the workpiece around a central axis while cutting tools are applied to shape and remove material as needed.

CNC lathe machines are particularly suited for various processes, including cutting, sanding, facing, drilling, turning, and knurling. Machinists often use these machines to produce items such as gun barrels, camshafts, crankshafts, automobile components, dining tables, baseball bats, furniture legs, and musical instruments.

CNC Laser Cutters

CNC laser cutters, much like their plasma counterparts, are capable of slicing through a variety of materials, including plastic, paper, fabric, metals, and hardwood. However, instead of utilizing plasma, these machines harness a concentrated beam of light, commonly referred to as a laser, to execute their cutting tasks.

This method results in a smaller point of contact and a more focused spread, which enhances perfection and improves the quality of the surface finish. Industries such as aerospace, automotive, medical, and engraving rely on CNC laser cutters for the production of parts and components.

CNC Drilling Machine

The CNC drilling machine represents another widely used form of CNC machining and homemade CNC cutters. True to its name, this equipment is designed specifically for creating holes in various materials, whether for screws, secondary assembly, or purely aesthetic purposes.

Employing rotating drill bits, these machines can produce cylindrical holes in the workpiece, utilizing different types of drills such as peck drills, spotting drills, chucking reamers, and screw machine drills.

CNC drilling machines find applications in several fields, including woodworking and furniture production, automobile manufacturing, astronautics, shipbuilding, mold making, engineering machinery, and many more.

CNC Waterjet Cutters

CNC waterjet cutting is a highly adaptable manufacturing technique that employs a high-pressure water stream, often combined with abrasive substances, to achieve precise cuts in a variety of materials.

The integration of CNC technology facilitates automated management of the cutting process for the creation of complex designs and shapes with little human involvement. This method is particularly esteemed for its capability to slice through an extensive array of materials, such as metals, glass, stone, and composites, while avoiding the formation of heat-affected zones that could compromise the material’s properties.

The uses of homemade CNC cutter waterjet are extensive and cover numerous industries. In the manufacturing sector, it is frequently utilized to produce components for aerospace, automotive, and industrial machinery.

This technique is applied to craft intricate designs in stone and tile in construction and architecture. It is also utilized in the art sector for the creation of detailed sculptures and installations. Its capacity to deliver clean cuts with minimal waste makes it an eco-friendly choice, further increasing its attractiveness across different domains.

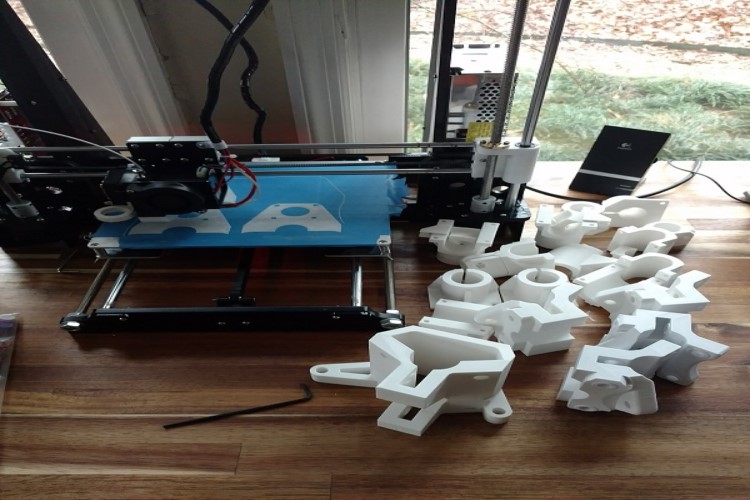

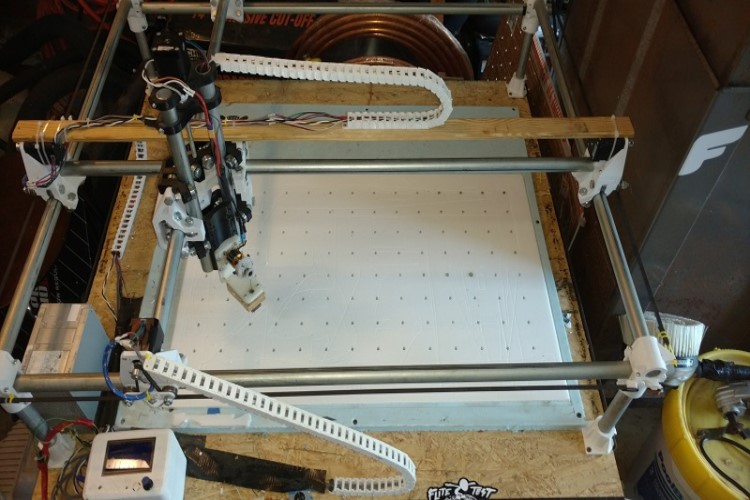

Homemade CNC Cutter: CNC Router

A CNC router is another flexible homemade CNC cutter that automates the processes of cutting, carving, and engraving a variety of materials, such as wood, plastic, metal, and composites, using a rotating cutting tool. Like other types of CNC machines, CNC router functions based on designs generated by a computer, enabling high levels of exactitude and consistency in manufacturing.

CNC routers are commonly utilized in industries like woodworking for furniture and cabinetry, sign-making for custom signs, and prototyping for detailed models. They are also used in the creation of decorative features, architectural elements, and even in the automotive and aerospace industries for lightweight components, demonstrating their multiple uses and effectiveness in contemporary manufacturing.

CNC Stone Cutter

Another type of homemade CNC cutter is a CNC stone cutter that can cut and shape different types of stone, like granite, marble, and quartz. Thanks to its advanced technology, this machine can create detailed designs and patterns with great perfection.

CNC stone cutters typically use methods like water jet or diamond blade cutting, which provide clean cuts and help reduce waste. They are commonly used for making countertops, tiles, sculptures, and architectural features.

CNC Knife Cutter

A CNC knife cutter is a specialized machine that cuts materials using a sharp blade, all controlled by a computer system. This type of cutter is often used in industries that need precise cutting of softer materials, such as fabrics, foam, paper, and plastics.

CNC knife cutters can handle a variety of cutting techniques, from straight cuts to complex designs and even 3D shapes, depending on the type of blade used.

Conclusion

The types of CNC machines including homemade CNC cutters are numerous, each one designed for a specific application. CNC router, CNC stone cutter, CNC plasma and laser cutters, and CNC waterjet are among the many types of CNC machines to name.

You can get the different parts of your desired machine with high quality from Maple CNC, or you can purchase the whole kit ready to install for higher precision.