Every CNC machine requires high-quality electronic machine parts Inc. to function effectively and efficiently. The performance and precision of a CNC machine are heavily influenced by its electronic components; thus, investing in superior parts can significantly enhance its overall performance. In this article, we will explore the essential electrical components needed for CNC machines and examine the current market trends in the electronic parts industry.

All the Electronic Components of CNC Machines

The heartbeat of precision and efficiency of CNC machines lies within their key electrical components. These include advanced electrical control systems, high-performance servo drives, robust motors, and sensitive sensors. Here is an overview of the essential electrical components that ensure the precision and reliability of CNC machine tools.

CNC Control Unit

Often referred to as the brain of the CNC machine, this unit interprets G-code and manages the machine’s operations. It typically comprises a computer, microcontroller, or PLC (Programmable Logic Controller) and connects with other machine elements through a range of input/output ports.

Power Supply Unit (PSU)

This electronic machine part Inc. is responsible for converting and delivering electrical power to the various parts of the CNC machine. It ensures that stable voltage levels are maintained, which are crucial for the operation of the control system and other electrical components.

Servo Motors and Drives

Servo motors are used to achieve precise control over velocity, acceleration, and angular or linear positioning. These motors receive control signals from the CNC control unit, which in turn modulates the power supplied to them via servo drives.

Stepper Motors and Drives

Stepper motors, as one of the important electronic machine parts Inc., facilitate accurate control of position and speed without relying on feedback systems. The stepper drives manage the sequence of electrical pulses that activate the stepper motors.

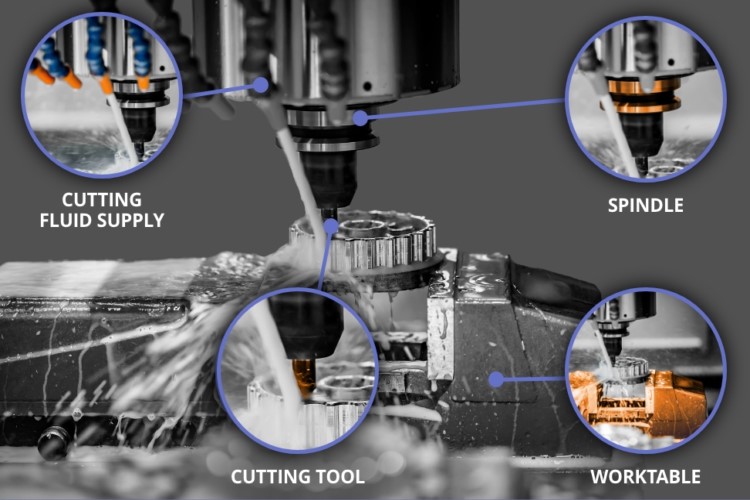

Spindle Motor and Drive

The spindle motor is responsible for driving the main spindle of the CNC machine. Its speed and torque are regulated by the spindle drive, which often utilizes variable frequency drives (VFD) for optimal performance.

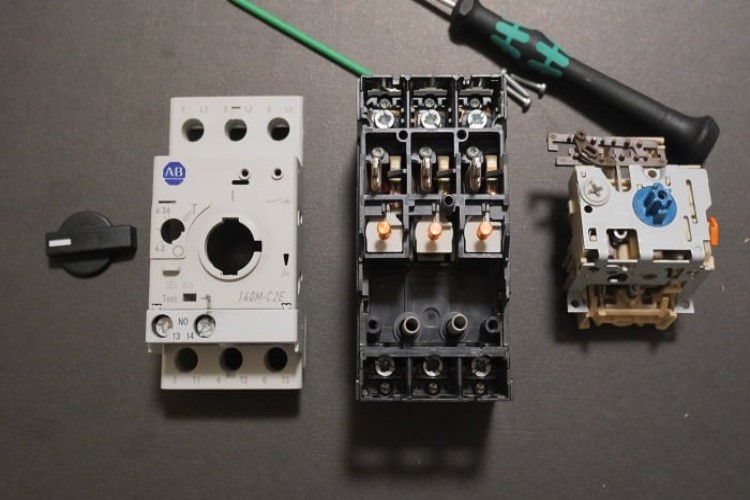

Relays and Contactors

Operating as electrically controlled switches, these electronic machine parts Inc. manage high-power devices using low-power signals. In contrast, contractors serve as robust relays designed specifically for toggling high-power circuits, such as those found in spindle motors.

Encoders and Feedback Devices

The CNC control unit relies on encoders to relay information about position and speed. While linear encoders track straight-line movements, rotary encoders focus on measuring rotational dynamics.

Limit Switches and Proximity Sensors

Limit switches play a crucial role in detecting whether an object is present or absent, thereby ensuring that machine components do not exceed their designated travel limits. Meanwhile, proximity sensors identify nearby objects without the need for physical contact.

Control Panel

This electronic machine part Inc. is the operator’s gateway to the CNC machine, featuring an array of buttons, switches, display screens, and input devices such as keyboards and touchpads.

Safety Interlocks

To guarantee the CNC machine operates safely, safety interlocks prevent certain actions from occurring unless specific conditions are satisfied. These systems are often linked with emergency stop buttons and safety doors.

Circuit Breakers and Fuses

Circuit breakers are, in fact, the guardians of electrical circuits, shielding them from overcurrent and short circuits. Fuses, on the other hand, provide a protective measure by melting when the current surpasses a predetermined limit.

Cooling Fans and Heaters

To avert overheating of electrical components, cooling fans are another electronic machine part Inc every CNC machine needs. Conversely, heaters are utilized in environments where maintaining temperature is essential for optimal component performance.

Wiring and Connectors

Reliable electrical connections between components hinge on high-quality wiring and connectors. Effective cable management is vital to prevent interference and uphold signal integrity.

CNC Electronic Parts’ Current Market Trends

The swift evolution of CNC machine tools has catalyzed remarkable progress within the electrical component sector. For manufacturers striving to remain competitive and innovative, grasping the latest trends in this field is crucial.

Merging IoT and Smart Technologies

A dominant trend shaping electronic machine parts Inc. is the incorporation of the Internet of Things (IoT) and smart technologies. This integration facilitates real-time monitoring, predictive maintenance, and remote diagnostics for machines.

Increasingly, electrical components like sensors, actuators, and communication modules are being outfitted with IoT capabilities, which significantly boosts operational efficiency and minimizes downtime. To align with the demands of Industry 4.0, manufacturers are prioritizing the creation of robust, secure, and interoperable IoT-enabled components.

Focus on Energy Efficiency

In the CNC machine tool industry, energy efficiency has emerged as a critical priority, influenced by environmental regulations and economic factors. Advanced energy-saving features are being incorporated into electronic machine parts Inc. such as servo drives, motors, and power supplies.

There is a growing preference for variable frequency drives (VFDs) and energy-efficient motors, which help reduce energy consumption while maintaining performance standards.

The implementation of regenerative braking systems in CNC machines helps with energy recovery during braking, further improving efficiency and lowering overall operational costs.

Progress in Control Systems and Software

The effectiveness and performance of CNC machine tools heavily rely on their control systems and software. Innovations in electrical components, including Programmable Logic Controllers (PLCs) and CNC controllers, are driving advancements that support faster processing speeds, greater precision, and better integration with other manufacturing systems.

A notable trend is the adoption of open architecture and modular designs, which facilitate easier customization and scalability of CNC machines. More than that, improvements in software algorithms for motion control and synchronization are enabling intricate machining tasks to be executed with enhanced accuracy and repeatability.

Eco-Friendly Manufacturing Approaches

The movement towards eco-friendly manufacturing is shaping the evolution of the electronic machine parts Inc. used in CNC machine tools. Manufacturers are increasingly opting for sustainable materials and processes when producing items like circuit boards, cables, and connectors. There is a concerted effort to enhance the lifecycle of these electrical components to emphasize recyclability and minimize electronic waste from design through to disposal.

Going for sustainable practices not only meets regulatory standards but also resonates with environmentally aware consumers and bolsters corporate social responsibility (CSR) initiatives.

Enhancements in Safety and Reliability

Safety and reliability are paramount in all CNC machines, as any malfunction can lead to significant downtime and safety risks. Continuous improvements are being made to the electronic machine parts Inc. such as emergency stop switches, safety relays, and interlock systems to comply with rigorous safety regulations.

Advanced diagnostic features and self-monitoring capabilities in CNC machines allow for the early identification of potential issues for proactive maintenance and reducing unexpected downtime. The use of redundant systems and fail-safe designs guarantees uninterrupted operation, even in demanding industrial settings.

Conclusion

Electronic machine parts Inc. plays a crucial role in the efficiency of CNC machines. Selecting the right components in line with current market trends is essential, as subpar quality can hinder machine performance and negatively impact energy consumption and the environment. Maple CNC provides top-quality electronic components that encompass all the desirable features.