In woodworking and manufacturing, the CNC router wood carving machine is a game-changer that blends precision with creativity. In this article, we’ll take a look at the CNC routing process, breaking down each step from design to quality control. We’ll also share tips on keeping your machine in great shape and understanding its quirks, so both newbies and pros can get the most out of their CNC routing experience.

The Stages of the CNC Routing Process

CNC routing involves a careful sequence of stages, each one important in its own right, working together to create a final product that meets exact specifications and boasts high-quality finishes. Let’s take a stroll through these stages:

Design Creation

The CNC routing process begins with design creation, where the magic starts. This is the stage where designers use CAD software to draft detailed models, laying the groundwork for what will eventually come to life from the CNC router wood carving machine.

It’s a crucial step; the creativity and precision applied here set the tone for the quality of the finished piece. Whether it’s for complex machinery parts or beautiful art pieces, this design stage captures the vision in a digital format, ready to be transformed into reality.

Conversion to CNC Language

Next up is the exciting phase of converting the CAD model into a language that the CNC machine can understand, G-code. This is where CAM software steps in, translating all those intricate design details into instructions that the machine can execute.

But it’s not just a simple translation; it’s about making sure the CNC router wood carving machine can accurately follow the design paths, taking into account things like tool paths, cutting depths, and material properties.

Material Selection and Preparation

Choosing the right material is more than just picking something that looks good. You have a variety of options, from softwoods and hardwoods to metals and plastics, and each one is selected based on what your project needs in terms of durability, finish, and strength.

Once you’ve made your choice which is typically wood as the machine is designed for it, it’s time to prepare the wood by cutting it to the right size and securing it to the CNC table. This step is super important because it ensures everything stays stable and accurate while the router does its thing.

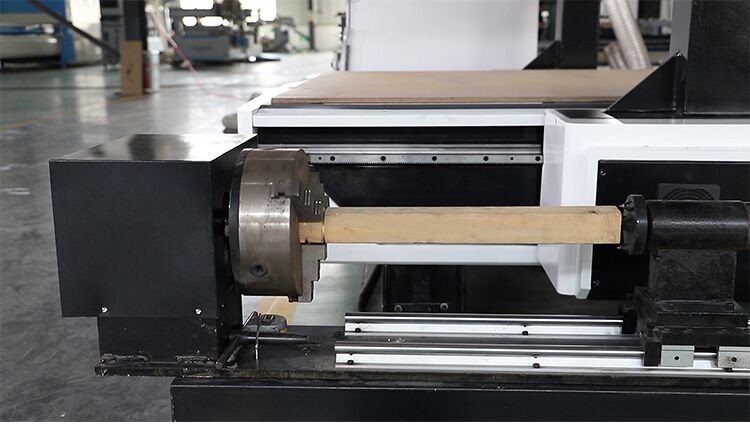

Machine Setup

In this stage, you need to get the CNC router wood carving machine all set up. This means loading the right tools, like drill bits and cutters, and adjusting settings such as speed, feed rate, and tool paths to match the material and design.

Getting this setup just right is key to making sure everything runs smoothly and accurately, which affects everything from the quality of the cuts to how long the tools last.

CNC Routing Process

Now that everything is prepped and ready to go, it’s time for the CNC routing process to be done. The CNC router wood carving machine comes to life, cutting and carving according to the G-code instructions.

This is the moment when your digital design starts to take shape, with the router carefully following the programmed paths to create the physical object.

Post-Processing

Post-processing could include sanding, painting, or even assembling the piece, turning it into the beautiful final product you envisioned. Post-processing is super important not just for how the piece looks, but also for how well it works. You want to make sure it aligns perfectly with your design and is all set for its intended use.

Quality Control

Quality control is where you make sure that everything meets your high standards and specifications. You need to carefully inspect the piece for accuracy, dimensions, and finish, ensuring that every step of the CNC routing process has been spot on.

The Time CNC Routing Typically Takes

CNC routing times can really vary depending on a few different factors. For simple cuts, you might be looking at just a few minutes, but for those more intricate designs, it could take several hours using the CNC router wood carving machine.

One of the biggest things that affects the time is how complex the design is. If you have detailed engravings or intricate patterns, those require careful movements and often need multiple passes, which can stretch out the routing time.

The material you choose is also important. For example, routing through harder wood usually takes longer than working with softer types of wood, since you have to go a bit slower to keep everything in good shape.

The type of CNC router you are using matters too. High-performance machines with powerful spindles and advanced features can get the job done faster than hobbyist models. Plus, deeper cuts often need multiple passes, which can add to the time.

If your project requires switching between different tools, you will want to factor in some extra time for those tool changes as well.

Helpful Tips to Consider in Working with CNC Routers Wood Carving

The CNC router wood carving machine is an amazing tool that offers a lot of versatility and efficiency, but it does come with a few common pitfalls that can impact both the quality of your work and the lifespan of your machine. To help you out, here are six tips to keep in mind:

Don’t Skip Machine Maintenance

Regular maintenance is key! If you neglect it, you might face premature wear, inaccurate cuts, or even machine failure. Make it a habit to clean your machine, lubricate the moving parts, and check for any signs of wear.

Choose the Right Tool

Using the wrong tool for a specific material or task can lead to frustrating results, like poor cuts or even tool breakage. Always take a moment to match the tool to the material and the job at hand.

Mind Your Feed and Speed Rates

Setting these rates too high or too low can cause issues like burn marks or a rough finish. It’s a good idea to consult tools and material guides to find the sweet spot for your settings.

Secure Your Materials

If your materials aren’t held down properly, they can shift during routing, which can lead to inaccuracies or damage to your CNC router wood carving machine. Make sure to use the right clamps, vacuum tables, or t-slot systems to keep everything firmly in place.

Keep an Eye on Tool Wear

Over time, tools can wear down, which affects precision and quality. Regularly check your tools for wear and replace them when necessary to keep your cuts looking great.

Stay Updated with Software and Calibration

Outdated software or uncalibrated machines can lead to errors in your routing process. Make it a point to keep your software up to date and calibrate your machine regularly for the best results.

Conclusion

To wrap things up, by getting to know the CNC routing process you can really boost your skills and create amazing pieces. Plus, following some simple tips from the experts not only enhances your results but also helps your CNC router wood carving machine last longer. With these practices, as a beginner or experienced woodworker, you can truly make the most of CNC technology in your projects.