CNC machines, such as mills and lathes, play a crucial role in today’s manufacturing landscape. They operate with minimal human involvement, which helps businesses save both time and money. These machines are engineered to produce parts automatically from various materials. To gain a clearer picture of their functionality, let’s explore the major parts of CNC machines and how they operate.

What Are the Major Parts of CNC Machines?

CNC machines are made up of several complex parts that work together to guarantee efficient operation and the rapid production of precise components. The following sections provide an overview of each of these parts.

Machine Control Unit (MCU)

The Machine Control Unit, or MCU, is a sophisticated amalgamation of software and hardware that plays a pivotal role in the operation of the machine. It deftly interprets the G-code received from the input device, transforming it into precise instructions that guide the machine and its tools with unwavering accuracy.

As one of the major parts of CNC machines and the entire system, the MCU orchestrates the movement of servo motors along multiple axes to make sure that everything is operating seamlessly. It also meticulously verifies the positioning of tools post-movement, manages the tool changers, and regulates the activation of the coolant, all of which contribute to the harmonious functioning of the machine.

Input Device

The input device is the gateway through which CNC programs are integrated into the machine. This process can be elegantly simple, ranging from the tactile experience of a keyboard for direct G-code command entry to the convenience of a USB flash drive preloaded with the completed program. Alternatively, one might include the modernity of wireless communication as it allows for easy downloads from another computer and ensures the workflow goes smoothly and efficiently.

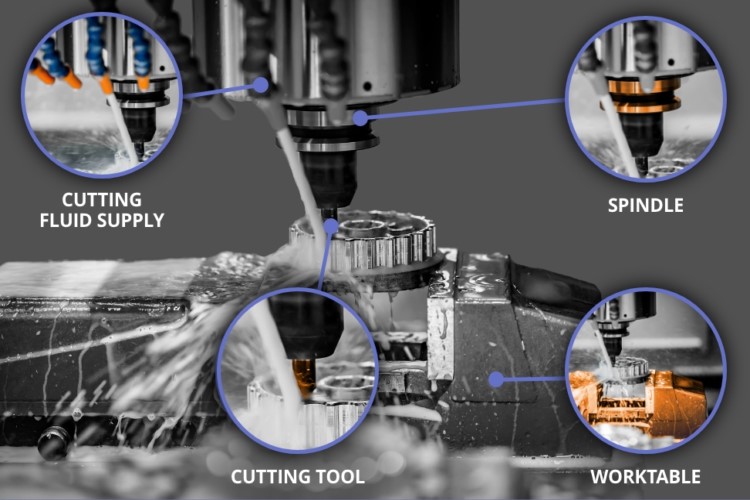

Machine Tools

When we talk about machine tools as major parts of CNC machines, we’re generally referring to the various tools used in machines, with cutting bits being the most common. Different types of CNC machines handle these tools in different ways. For instance, CNC lathes keep their tools in one place and move the spinning workpiece into the machine to make cuts.

On the other hand, CNC mills do the opposite by moving the spinning tools toward a stationary workpiece. More advanced machines, like 5-axis CNCs, can move both the tools and the workpiece simultaneously.

These tools are usually stored in a section of the machine known as the tool library. When a tool is needed, the machine automatically retrieves it from the library, uses it for the job, and then returns it before picking up any other tools it might require.

Driving System

The driving system which is one of the major parts of CNC machines, is essentially the set of motors that move the tools around. In a typical CNC mill, the bed shifts side to side (on the x- and y-axis), while the tool moves up and down (on the z-axis). In a CNC lathe, the cutting tool travels in conjunction with the rotating workpiece, extending towards the outer edge as it spins, rather than traversing across the surface of the part. To keep everything running smoothly and in sync, we use servo motors, ball screws, and linear guides.

Feedback System

The next major part of CNC machines is the feedback system which works as a safety net. While the driving system is highly precise, this closed-loop control system checks to make sure that the parts are moving exactly where they need to go.

If something is slightly off, it can make adjustments using encoders, which are sensors that track the position of each component. Probes also help by measuring the actual workpiece to ensure everything is on track. If any tweaks are necessary, the machine will automatically make those adjustments.

Bed of the CNC Machine

One of the major parts of CNC machines is the bed where you can place the raw material to work on it. It features various holes or t-slots that are used to secure the object in position. Traditional machine beds typically only move side to side (on the x and y axes), but more advanced 5-axis machines can also rotate along these axes.

Display Unit

The display unit is pretty straightforward. It’s a screen that shows all the essential information while the machine is operating, such as settings, G-code, and the current status. Some machines come with large, high-definition screens that provide a lot of details, while others may have smaller displays that only show the most critical information.

Headstock

The headstock, one more major part of CNC machines, is found on the left side of a CNC lathe. It contains the bearings, major drive, and gears that cause the chuck to spin. While it’s enclosed for safety, you can access it by removing a few inspection panels.

Tailstock

The tailstock provides support for one end of a lengthy, cylindrical workpiece, whereas the chuck secures and rotates the opposite end. This part is crucial because it prevents the material from bending during the machining process. It can slide along the z-axis to fit different lengths of material. So, it is especially useful for working with items like shafts or screws.

Tailstock Quill

Another major part of CNC machines is called tailstock quill. Inside the tailstock is the quill, which has a cone shape and aligns with the spindle and chuck. It rotates freely to keep the material centered.

For longer pieces, a blind hole is often drilled into the end so the quill can fit inside for added support. After the tailstock is positioned near the workpiece, the quill is advanced by applying pneumatic or hydraulic force.

Footswitch or Pedal

These pedals are typically found only on lathes. These major parts of CNC machines control the activation and deactivation of the chuck and tailstock quill, which allows the operator to easily load raw materials into the machine and unload finished parts. CNC mills usually don’t have these pedals because the parts are already supported on the bed, and operators can use both hands when loading and unloading.

Chuck

The chuck is a key component of lathes, designed to grip the workpiece during machining. The spindle keeps it spinning at high speeds. Generally, a chuck has three or four grips that are actuated pneumatically or hydraulically.

Three-jaw chucks are self-centering, meaning all the grips move together evenly. Four-jaw chucks are adjustable, allowing each grip to move independently. They offer more features, such as greater precision for eccentric or off-center cutting, and they handle material inconsistencies better.

Control Panel

This major part of CNC machines is the machine’s brain. It contains the input device, display screen, keyboard, and various control buttons. Usually, it’s connected to the machine but can be adjusted on an extendable arm, allowing you to pull it closer or position it wherever you need for easy access.

Conclusion

CNC machines consist of various components, each designed for a specific function. The major parts of CNC machines include the driving system, input device, MCU, and many more. Understanding these components and their performance can enhance your knowledge when selecting a CNC machine. Plus, this insight will assist you in replacing or upgrading parts as necessary.

At the Maple CNC store, you can not only learn about each component but also receive expert advice and make high-quality purchases.