The CNC router is a highly versatile machine widely employed across various industries. Its effectiveness is largely dependent on the diverse range of router tool parts it can accommodate, each tailored to specific applications. To maximize the potential of a CNC router, it’s crucial to understand its tooling options so that you can select the most suitable ones for your material and project requirements.

Cutting Tools

A router can feature numerous models of cutting bits, enabling it to tackle different projects with ease. Let’s get to know the most common ones of them:

Straight Bits

Straight bits are primarily used for general cutting, including creating slots, dadoes (notches cut into the surface of the wood), and rabbets (a recess or groove). They have a straight cutting edge and come in various diameters and lengths to accommodate different applications.

V-Bits

V-bits feature a pointed, V-shaped cutting edge for creating grooves, decorative edges, and lettering. These router tool parts are commonly used in sign-making and for adding intricate details to wood surfaces.

Profile Bits

Profile bits are used to create custom shapes and profiles along the edges of wood pieces. They are available in many designs, allowing for decorative edges that add character to furniture and cabinetry.

Engraving Bits

Engraving bits are small-diameter bits designed for creating detailed designs and lettering. These router tool parts have a sharp point that can engrave intricate patterns onto a variety of materials, including wood, plastic, and metal.

Spiral Bits

Spiral bits feature a helical cutting edge that allows for a smoother cut compared to straight bits. The spiral design helps to pull chips upward and away from the cutting area.

Router Bits with Replaceable Tips

These router bits feature tips that can be replaced once they become worn down. This design extends the life of the tool, as you only need to replace the cutting portion rather than the entire bit.

Core Box Bits

Core box bits create precise holes with rounded bottoms for making recesses such as those needed for hinges and other hardware. These router tool parts are useful in joinery and for creating decorative flutes.

Shear Clear Bits

Shear clear bits are specifically designed for cutting acrylic and other types of plastics. They are engineered to minimize chipping and melting, providing smooth edges to the cut material. They are essential for projects that require clean and precise finishes on plastic surfaces.

Forming Bits

Forming bits are used to create decorative edges and shapes, similar to profile bits. They offer various designs to give a distinctive look to the edges of workpieces. They are popular in furniture making and cabinetry.

Slot Cutter Bits

Slot cutter bits router tool parts are designed for cutting slots that will accommodate T-tracks and other accessories. They are typically used in jigs and fixtures and for creating grooves for joinery purposes.

Keyseat Cutter Bits

Keyseat cutter bits are specifically designed to create keyways or grooves in shafts and pulleys. These grooves are essential for securing components in machinery, as they allow for the insertion of a key that locks parts into place.

Countersink Bits

Countersink bits are used to create countersunk holes for screws, allowing the screw heads to sit flush with or below the surface of the material. These router tool parts are commonly used in woodworking to provide a clean finish and prevent screw heads from protruding.

Reamer Bits

Reamer bits are designed to enlarge and smooth existing holes. They provide a precise finish to previously drilled holes and can be used to ensure that holes have a consistent diameter or to correct any irregularities in the holes.

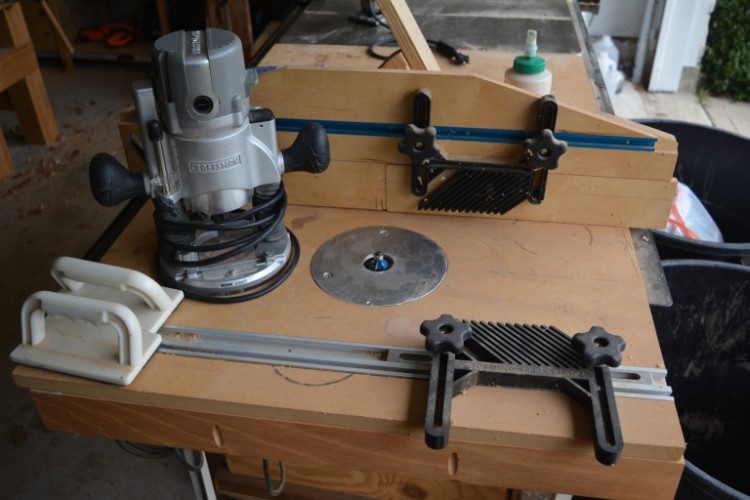

Accessories

Along with the cutting tools, accessories are important router tool parts that help the machine operate in its best way:

Tool holders

Toolholders serve as a connection between the collets and the spindle of a router or CNC machine. They provide a sturdy mounting point for the collets, ensuring that the router bits are accurately aligned with the spindle. Toolholders come in different designs to accommodate various tools and attachments.

Tool Changers

Tool changers allow for the automatic switching between different tools without manual intervention. These systems enhance productivity by enabling a CNC machine to run multiple operations sequentially, reducing downtime between tool changes. Tool changers can hold several router tool parts and replace them as needed during the machining process.

Vacuum System

A vacuum system is used to remove dust and debris during cutting operations. It typically consists of a powerful vacuum pump that creates suction to pull away chips, sawdust, and other waste materials from the work area. This not only helps to keep the workspace clean but also improves visibility and protects sensitive machinery parts from debris.

Dust Hood

A dust hood is a component typically mounted near the cutting area that collects dust and debris at the source. This router tool part is designed to channel the waste material into a vacuum system or dust collection bag. Effective dust hoods help reduce airborne particles to improve air quality and the work environment.

Tool Lifters

Tool lifters are mechanisms that can automatically raise and lower cutting tools. This automation allows for greater precision when changing tools and can facilitate rapid advancements during machining processes. The router tool parts are particularly useful in applications where various depths of cuts are required or when switching between tools frequently.

Coolant Systems

Coolant systems are used to cool the cutting tools and reduce friction during machining. These systems typically involve the application of a liquid coolant that not only helps to regulate temperature but can also improve the finish of the workpieces and extend the life of cutting tools by reducing wear.

Air Blast Systems

Air blast systems utilize compressed air to remove chips and debris from the cutting area. These router tool parts help maintain a clear view of the cutting operation and ensure that the material does not interfere with the tooling process. Air blasts can quickly clear excess material, improving cutting efficiency.

Touch Plates

Touch plates are used for tool setting and calibration in CNC routers. They help establish precise tool offsets and ensure that the cutting tool is positioned correctly relative to the workpiece. This adjustment is crucial for achieving the desired depth and accuracy in machining operations.

Waste Boards

Waste boards are sacrificial surfaces placed on top of the machine table to protect it from damage during cutting. They allow users to make cuts without harming the underlying table and can be easily replaced when worn out. Waste board router tool parts also facilitate the removal of chips, as materials can easily be cleared from their surface.

Fixturing

Fixturing refers to the various methods and devices used to hold workpieces securely in place during machining. Effective fixturing is essential for maintaining precision and repeatability in routing operations. Different types of fixtures can include clamps, jigs, and beds that conform to the shape and size of the workpiece.

Conclusion

Selecting the ideal CNC router tool parts is crucial for successfully executing your projects with precision and efficiency. To make an informed decision, it’s essential to consider various factors, including the materials you will be working with, the specific type of tasks at hand, and the desired output quality. Seeking guidance from reputable sources, such as Maple CNC, can provide valuable insights and ensure that you choose the right tool for your specific needs.