Industrial CNC routers are handheld cutting tools that are super smart because they’re controlled by a computer. Today, many great industries benefit from the magic of these machines as they can help you create high-quality products while remaining cost-effective. No more stressful moments of missing deadlines because of parts that just don’t fit, and if you happen to make a mistake, with a CNC router, you can easily adjust and tweak your parts in no time.

Top 8 Industries That Are Benefiting from CNC Routers

In today’s industries, the use of industrial CNC routers has become essential. Every industry aims to market its products with both superior quality and maximum quantity. CNC routers are utilized across nearly all sectors, and below, we will highlight the key industries that have transitioned to using these devices:

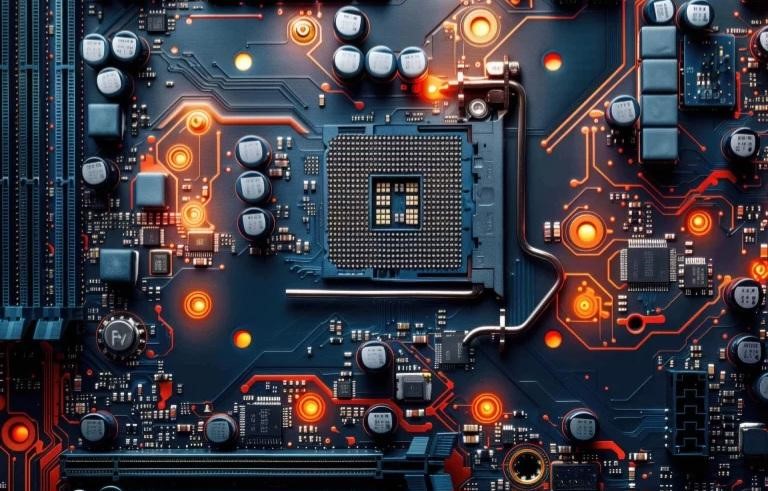

The industry of Electronic

The Electronic industry really thrives on components that have intricate details and come in all sorts of sizes. That’s where CNC routers come in, they can create connectors, PCBs, semiconductors, heatsinks, test fixtures, and housing components quickly and beautifully.

When it comes to testing new structures, making prototypes is a crucial step before diving into mass production. Industrial CNC router machines are fantastic for this because they can take a computer design and turn it into a working model that you can examine closely before going big.

And speaking of mass production, electronic components need to be produced in large quantities, which means you need some specialized machines. CNC router machines are perfect for this, as they allow manufacturers to run a small batch of production to test the prototypes before the main output.

The Industry of Aerospace

As you may know, precision as well as the utilization of high-quality parts is quite essential in aerospace engineering. That’s why the components often used in this industry need to be standardized and complex according to ISO 9001:2015 and AS9100D certifications.

For this standardization to happen, the aerospace industry relies heavily on industrial CNC routers to produce top-notch parts and equipment that are crafted to perfection. Skilled machinists utilize advanced 5-axis CNC router machines to create these aerospace components. These machines are fantastic because they control production across five axes to reach precise designs and efficient cutting speeds.

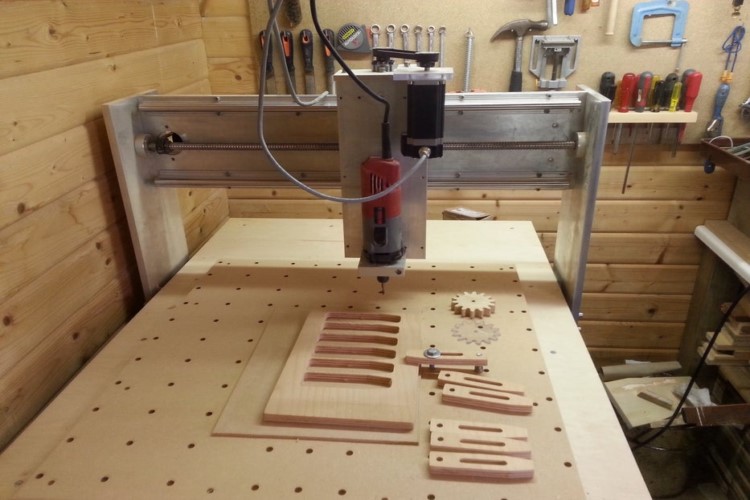

3D Modeling and Prototyping

Prototyping and 3D modeling are super important in many production processes, especially when it comes to getting things just right before going for mass production. Luckily, a CNC router machine whips up prototypes that include every little detail, even the screws.

Industrial CNC routers help with creating spare parts, tools, and components like gears with high precision to make the design turn out just right. They can scan, replicate, and engineer components with incredible accuracy, which really helps spark innovation and keep things moving forward. Plus, they work at lightning speed, often getting tasks done in less than half the usual time.

Manufacturers and entrepreneurs can create functional models of their ideas and see if they’re ready for mass production by using CNC routers.

The Industry of Stone Carving

Did you know that stone engraving has been around since ancient times? Early humans got creative with simple tools like hammers and chisels to carve stones for writing, decorating, and even making other tools.

Fast forward to today, and we still love using carved stones for all sorts of purposes. The big difference now is that we have amazing industrial CNC router machines that make the process so much easier and more precise.

CNC router machines are fantastic pieces of technology that help manufacturers carve shapes and write on ceramics and natural stones. They can do a variety of tasks, including stone letter carving, positive and line carving, 3D designs, shadow carving, and even hollowing and cutting.

Tombstones, signs, interior decorations, and outdoor panels are just a few examples of what a CNC router can do in this industry.

If you’re in the stone carving industry, investing in industrial CNC router machines is a smart move. Look for one that offers high-speed performance and has a sturdy motor. With the right machine, you can work with materials like bluestone, slate, marble, jade, granite, and more.

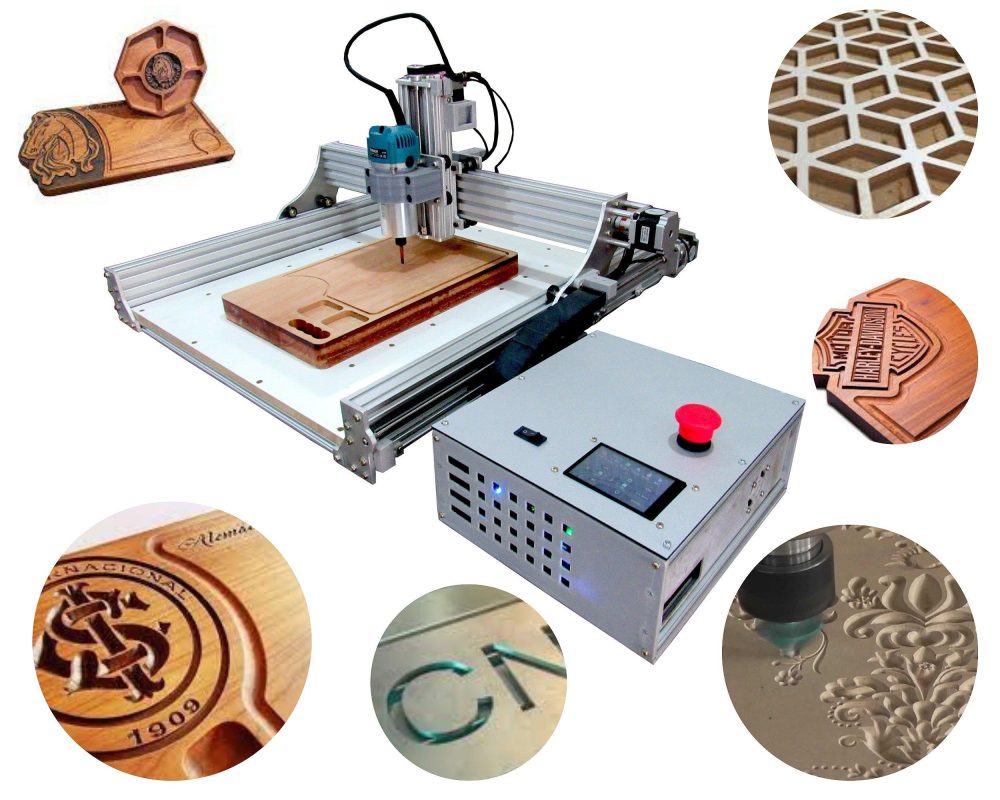

The Industry of Furniture

The furniture industry is really lucky to have CNC router technology at its fingertips. These amazing machines can handle all sorts of details, and when a skilled machinist is behind the controls, they can bring any design or concept to life.

Beautiful, intricate wood carvings as well as stunning, complex furniture pieces can now easily be done by a heavy-duty industrial CNC router. In fact, no matter if it’s budget-friendly or high-end pieces, furniture can be produced in just a few days instead of months. This ability to mass-produce has helped manufacturers take their businesses to exciting new levels.

The Industry of Automotive

CNC routers are like the unsung heroes of car manufacturing, helping to create everything from engine parts to stylish interior panels. These amazing machines deliver top-notch consistency and quality, which means production times and costs can be significantly cut down. This efficiency is a game-changer for automotive companies, which allows them to keep up with what the market demands and stay ahead of the competition.

What’s really great about industrial CNC router machines is their ability to work with a variety of materials used in making cars, including plastics, metals, and composites. Thanks to CNC technology, manufacturers can produce complex shapes and intricate designs, ensuring that every part fits just right and works perfectly. This level of exactitude is super important for keeping safety standards high and boosting vehicle performance.

The Industry of Packaging

CNC routers are fantastic tools that help create custom packaging solutions designed for specific products. This kind of flexibility means companies can whip up unique, high-quality packaging that not only looks great but also keeps products safe during shipping. Plus, being able to quickly produce prototypes allows businesses to adapt to market changes and meet customer needs more effectively.

Industrial CNC router machines can cut and engrave a variety of materials like cardboard, foam, and plastic. They’re perfect for making custom inserts, boxes, and displays that fit any product while providing the protection they need.

The Industry of Construction and Architecture

CNC routers make it so much easier to create detailed architectural components, either beautiful decorative elements or essential functional parts. With these amazing machines, architects and builders can bring their complex designs to life with incredible precision. Not only do they make structures look fantastic, but they also help improve efficiency and make better use of materials.

Industrial CNC routers work wonders with materials like plywood, MDF, and composites. Plus, these machines automate the production process ensuring that everything is consistently high quality and help speed up project completion.

Conclusion

Industries are being transformed by industrial CNC router applications, which improve precision, efficiency, and creativity. This impact extends beyond the fields mentioned; it is also influencing sectors such as musical instruments, art, education, and healthcare, among others. Before purchasing take your time to conduct thorough research and identify the machine that best suits your requirements.