CNC routers totally have changed the way we create everything. Whether you’re a skilled craftsman or a hobbyist, there’s a CNC router out there that’s ideal for you. But with so many options available in the market, how do you know which CNC router is right?

In this guide, we’ll break down the different types of CNC routers, their key features, and the necessary tools you’ll need to get started. This will help you find the excellent CNC router for sale that fits your projects.

7 Types of CNC Routers You Should Get to Know

As a hobbyist or a professional, you need to become familiar with the different types of CNC routers so that you can better determine which one is best fitted for your projects. Here are 7 common CNC routers to get familiar with:

Industrial CNC Routers

Industrial CNC routers serve as the backbone of CNC technology, particularly engineered for rigorous applications in manufacturing settings. Built to last, these routers can tackle heavy workloads quickly and accurately.

Typically, industrial CNC routers for sale come equipped with cutting-edge automation features, such as Automatic Tool Changer (ATC) systems and advanced software platforms that facilitate the performance of complicated tasks.

What sets these routers apart is their ability to produce high volumes with remarkable precision, basic for extensive manufacturing processes.

Desktop CNC Routers

Desktop CNC routers are, as their name implies, smaller models intended for placement on desks or within limited workshop spaces. These CNC routers for sale are perfect for smaller-scale projects, prototyping, and educational applications, as they are an inexpensive option for novices to CNC routing or those constrained by space.

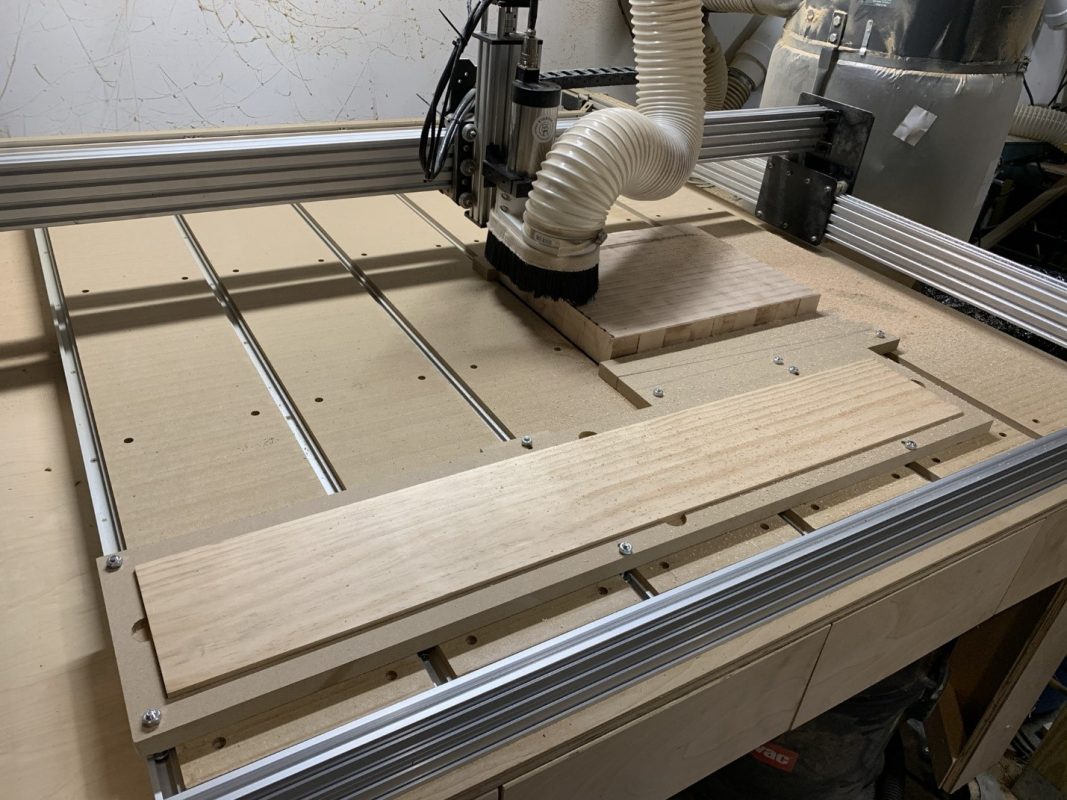

3-Axis CNC Routers

3-Axis CNC routers are the most general variety of available CNC routers for sale, invented to perform in three dimensions: X (horizontal movement), Y (front and back), and Z (vertical movement). This capability stimulates them to accomplish a diverse array of tasks, including cutting, drilling, and milling on flat materials.

Due to their straightforward function and effectiveness, 3-axis CNC routers are favored by both beginners and experienced users. They are especially practical for producing signs, crafting furniture, and executing detailed designs on flat surfaces.

4-Axis CNC Routers

Building upon the functionalities of 3-axis machines, 4-axis CNC routers for sale incorporate an additional rotational axis, which allows the workpiece to rotate along the X-axis. This enhancement provides greater versatility and facilitates the invention of intricate shapes and designs, including sculptures or parts that necessitate machining from multiple angles.

These 4-axis CNC routers are especially advantageous in sectors where accuracy and multidimensional cutting are critical.

5-Axis CNC Routers

5-Axis CNC routers for sale represent cutting-edge CNC routing technology that enables movement across five distinct axes at the same time.

With this functionality, you can cut intricate shapes and undercuts and enjoy superior surface finishes. These machines are particularly well-suited for sophisticated manufacturing tasks that demand detailed design, including components for the aerospace industry, architectural features, and precision-engineered parts.

ATC (Automatic Tool Changer) CNC Routers

ATC CNC routers come with a built-in automatic tool changer. This feature allows the machine to switch tools on its while routing, eliminating the need for manual changes. This functionality greatly boosts both productivity and efficiency, especially for tasks that involve various types of tools.

These CNC routers for sale are primarily utilized in manufacturing settings where speed and accuracy are critical.

Nested-Based CNC Routers

Nested-based CNC routers are engineered to enhance material efficiency and usage by strategically organizing cutting patterns to reduce waste. These routers are especially beneficial for sectors such as furniture manufacturing, cabinetry, and sheet metal work, where it is essential to maximize the yield from materials.

The Essential Tools for CNC Routing

Now that you understand the different types of available CNC routers for sale, it’s time to get to know the three main categories of tools equipped with these machines:

Cutting Tools

Central to the operation of CNC routing are the cutting tools that help you transform materials into a masterpiece. These instruments are more than mere metal components; they are the artisans that bring your creative ideas to life:

Ball Nose Cutters

Characterized by their rounded tips, ball nose cutters are perfect for 3D contouring and crafting complex shapes. You can use this tool when you want to produce sculptures or smooth finishes on the workpiece.

Make sure to purchase a CNC router for sale that provides all the cutting tools as they are designed for precise detailing in corners and tight areas that standard endmills may struggle to access.

V-Bits

As the name implies, V-bits have sharp V-like angles that enable you to create clean lines at various depths.

Straight Cut Bits

Any CNC toolkit must have this fundamental cutting tool because they are perfect for executing straight cuts and slots and dividing materials or shaping outlines.

Spiral Bits

Spiral bit with its helical design is another cutting tool in many CNC routers for sale and available in reliable stores. These bits are available in both upward and downward spirals and are suited for various materials and cutting requirements. One important feature of these bits is that they effectively remove material, minimize heat, and prevent chip accumulation.

Compression Bits

Compression bits effectively address issues like fraying and splintering, particularly in laminated materials. They utilize a combination of upward and downward spiral designs, which guarantees a smooth finish on both sides of the cut. These bits are ideal for working with plywood, laminates, and veneers.

Work Holding Tools

A good CNC router for sale not only must equipped with all cutting tools of all shapes and sizes, but it also should guarantee your material is securely held in place preventing any movement during routing:

Clamps

Clamps are among the most straightforward tools for holding materials. If you tend to work with different materials make sure the clamps are available in a different range of sizes and strengths to accommodate various materials and shapes. Choose clamps that provide adequate pressure without causing damage to the workpiece.

Vacuum Hold-down Systems

For fragile or oddly shaped materials vacuum hold-down systems in the CNC router for sale offer a consistent and secure grip across the entire surface of the workpiece. When doing high-precision tasks where traditional clamping methods may not be suitable, a vacuum hold-down system is recommended.

T-Slot Tables

Another important work-holding tool is called the T-Slot table which is very advantageous when you’re working on repetitive tasks as it provides various setup options and can significantly reduce setup time.

Measurement and Setup Tools

Measurement and setup tools are essential for ensuring that your material is properly positioned and that your machine is accurately calibrated:

Calipers

One measurement tool that you have to consider in any CNC router for sale is called a caliper. Calipers measure the thickness of materials and ensure that your cuts are precise to the last millimeter.

Tool Length Sensors

Tool length sensors streamline the task of establishing tool length offsets, which not only saves time but also minimizes the likelihood of mistakes. These sensors guarantee that each tool is accurately adjusted for depth, a critical factor in operations involving multiple tools.

Conclusion

Choosing the appropriate CNC router for sale can greatly improve your manufacturing efficiency, increase output, enhance precision, and ensure uniformity, all while lessening the reliance on specialized labor.

If you would like more comprehensive information about types of CNC routers and their tools make sure to consult with experts and make your purchase from reliable stores.