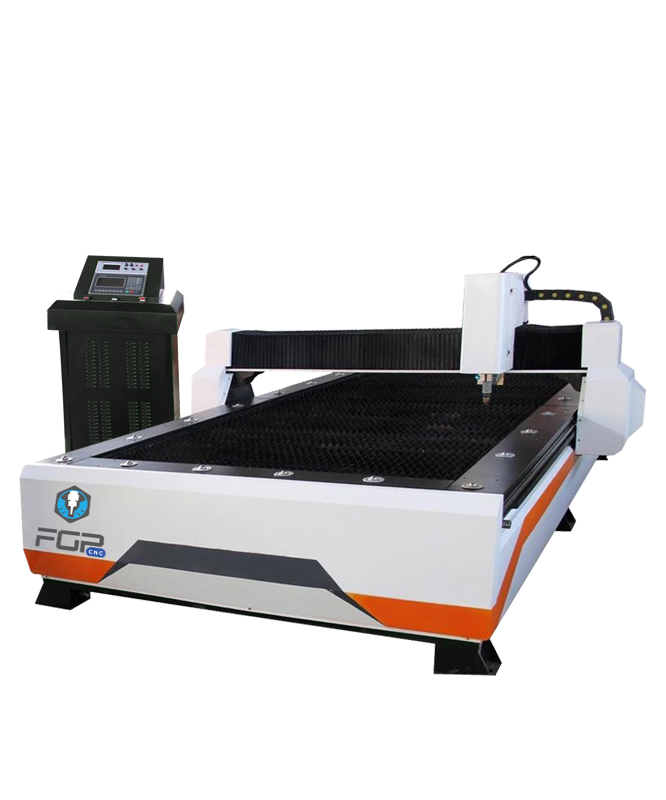

UPGRADE YOUR STEEL CUTTING OPERATIONS WITH EDGE SERIES PLASMA TABLE TECHNOLOGY

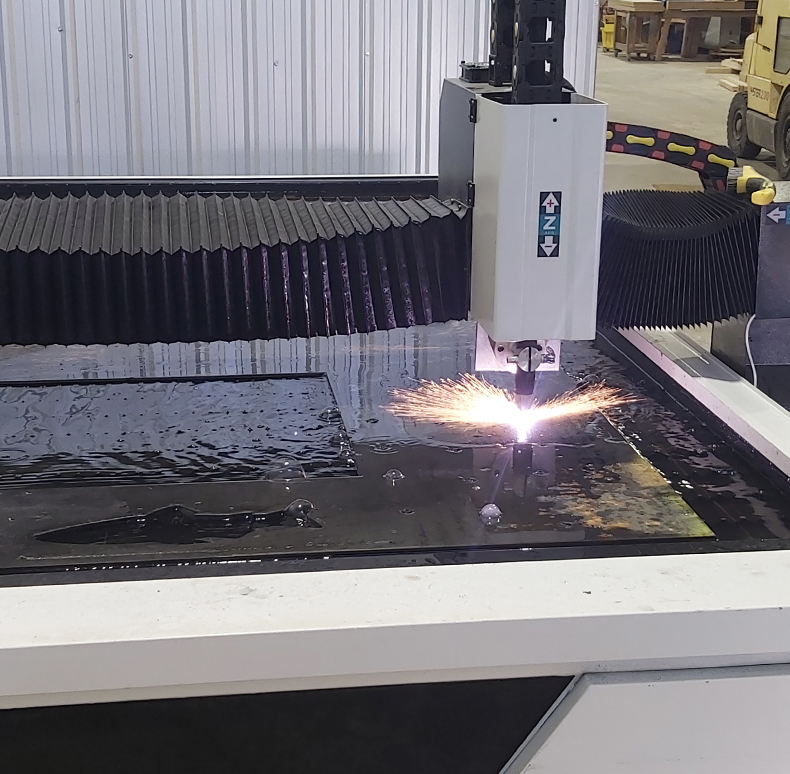

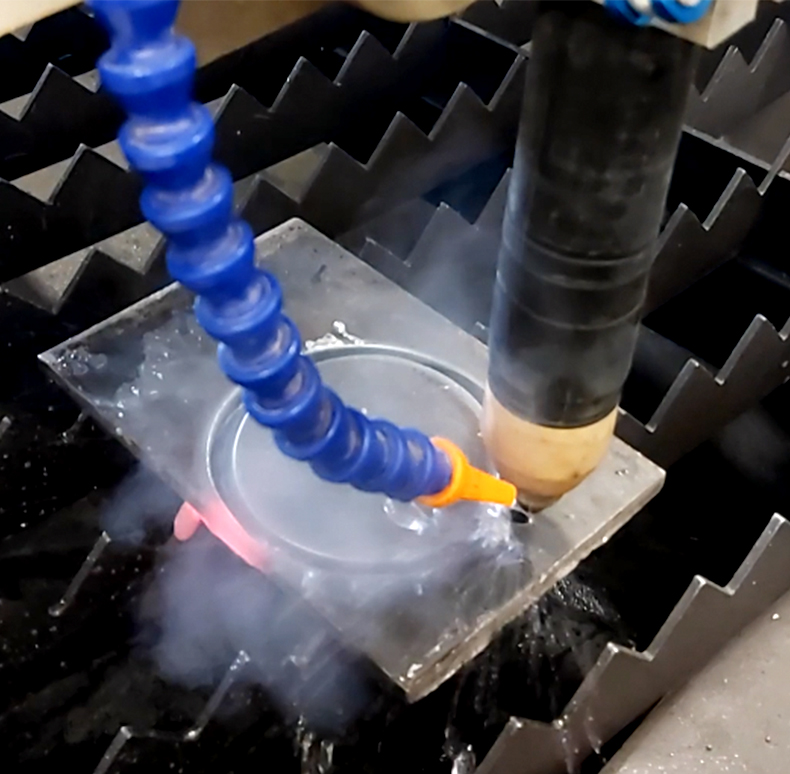

Looking to revolutionize your steel-cutting operations? Look no further than the EDGE Series Plasma CNC Table. With the ability to cutting and gouge up to 32 mm (1-1/4″) of steel with ease, speed, and precision. This cutting-edge plasma technology is a game-changer for businesses seeking to improve their productivity, reduce production costs, and enhance their final product quality. The EDGE Series Plasma CNC Table’s versatility, accuracy, and efficiency make it an indispensable tool for industries ranging from aerospace to automotive to construction. Plus, the technology’s ability to deliver precise and consistent plasma cuts eliminates the need for secondary finishing processes, saving you time and money. Upgrade your steel cutting operations with the EDGE Series Plasma CNC Table and experience the benefits of precision, versatility, and efficiency with plasma technology.

THE ULTIMATE SOLUTION FOR EFFICIENT JOB COMPLETION

The EDGE Series Plasma CNC Table, equipped with Hypertherm technology and Torch Height Controller, offers the ultimate solution for efficient job completion. With the ability to cut up to 32 mm (1-1/4″) of steel easily and precisely, this advanced plasma cutting system ensures consistent and accurate cuts while reducing production costs. Whether you take a job straight from CAD software or use the library of predefined shapes and objects, the EDGE Series Plasma CNC Table delivers precision, versatility, and reliability to meet the most demanding requirements of various industries.