The applicability of CNC router machines is endless with many different operations to perform according to specific projects. Each operation needs special types of equipment attached perfectly to the machine to get the best results. That’s why buying a CNC machine from a reliable CNC router shop is a must. In this article, we’ll introduce 13 different operations to be accomplished by your CNC router machine.

What Are the Different CNC Routing Operations?

In the following sections, you will gain insight into the various operations executed by CNC routers and their applications across a multitude of projects.

Engraving with CNC Routers

Engraving is an operation that requires a high level of precision, as a CNC router intricately carves patterns, letters, or images into a material’s surface. To achieve the requisite detail and depth, get machines from a CNC router shop that are equipped with fine-cutting tools or spindles.

This technique is widely applied in various fields, including the creation of intricate artwork on surfaces like wood, metal, or acrylic, as well as in designing signage that showcases detailed logos or typography. It is also utilized for customizing items by adding names, dates, or messages, and for producing industrial labels and control panels that require precise and durable markings.

Profiling Operation

Profiling is the process of cutting shapes from a material based on a defined outline, resulting in parts or features that have exact dimensions. Generally, to do this procedure you need machines with powerful drive systems and versatile cutting tools. You can find these machines from a reliable CNC router shop in Canada.

This operation plays a vital role in the fabrication of components designed with specific contours or shapes, ensuring that the edges of parts are meticulously trimmed to achieve smooth, finished boundaries, while also allowing for the creation of decorative panels and architectural elements that feature intricate outlines.

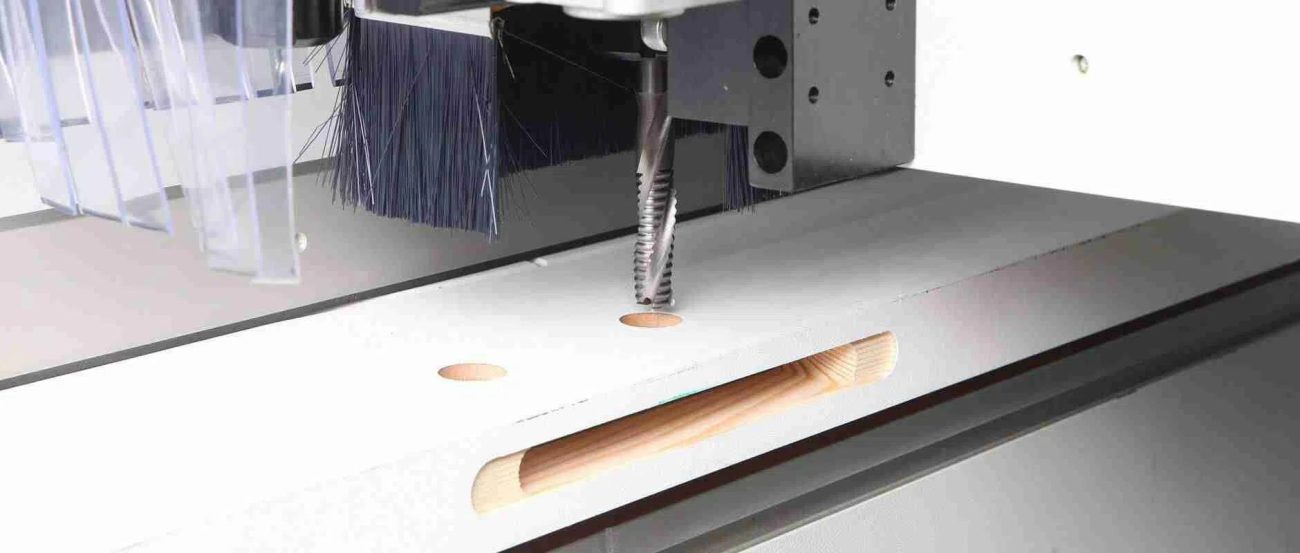

The Pocketing Technique

The process of pocketing involves the selective removal of material from a workpiece’s surface to form cavities or recesses of predetermined dimensions. This process is accomplished using CNC routers, which offer unparalleled control over cutting depths.

Pocketing finds applications in various manufacturing processes, including the creation of recesses to accommodate components or inlays, cutting slots or channels into a workpiece, and forming cavities in molds or dies for diverse purposes.

3D Carving Operations

CNC routing reaches new heights with 3D carving, transforming the process into a three-dimensional art form. This technique enables the shaping of materials to create designs that showcase depth, contours, and fine details.

To achieve optimal results, it is essential to purchase routers from a CNC router shop that offers sophisticated control across all three axes, as these advanced machines are utilized for a variety of applications, including the production of statues with intricate geometries, the manufacturing of molds for casting or thermoforming processes, and the creation of prototypes or models for testing or presentation purposes.

Drilling Technique Using CNC Routers

Drilling is another operation done by a good CNC machine with precise z-axis control purchased from a CNC router shop. The process entails the creation of cylindrical holes in a material, which can range from straightforward, straight bores to intricate, angled entry and exit points.

With your CNC machine, you can efficiently prepare components for assembly using screws, bolts, or dowels, while also creating ventilation holes or channels within various parts.

Reaming Operation

A CNC router with high stability and precision can do an operation called reaming which is a detailed finishing process to refine hole dimensions and improve surface quality.

To achieve precise outcomes such as exact diameters for holes that are ideal for tight-tolerance fittings, smooth and burr-free interior surfaces, and perfect alignment of components during assembly for seamless integration, it is essential to invest in a high-quality CNC router from a reputable CNC router shop in your country.

Ramping Operation

One more technique done by CNC machines comes from a trustworthy CNC router shop, called ramping. During this operation, you can do the process of entering or exiting the material surface at an angle in a gradual manner, as opposed to a direct, perpendicular plunge.

It’s important to note that by using this method, the load on the cutting tool is effectively reduced, which in turn minimizes wear and the risk of breakage.

Threading Operation

The process of forming a helical structure along a material’s surface is known as threading, and it is commonly used for screws, bolts, and fasteners. CNC routers perform threading by synchronizing the rotation of the spindle with the linear movement of either the tool or the material, utilizing specialized tool heads.

Achieving the precise control required for this operation is possible with advanced CNC systems that accurately adhere to programmed tool paths.

Slotting Operation

Slotting, which is a common requirement in various manufacturing tasks, is the process of cutting narrow grooves or slots into a material.

CNC routers, from a reliable CNC router shop, with their precise control over the X, Y, and Z axes, are ideal for slotting operations as the utilization of high-speed spindle motors and suitable cutting tools enables efficient material removal and the attainment of high-quality finishes.

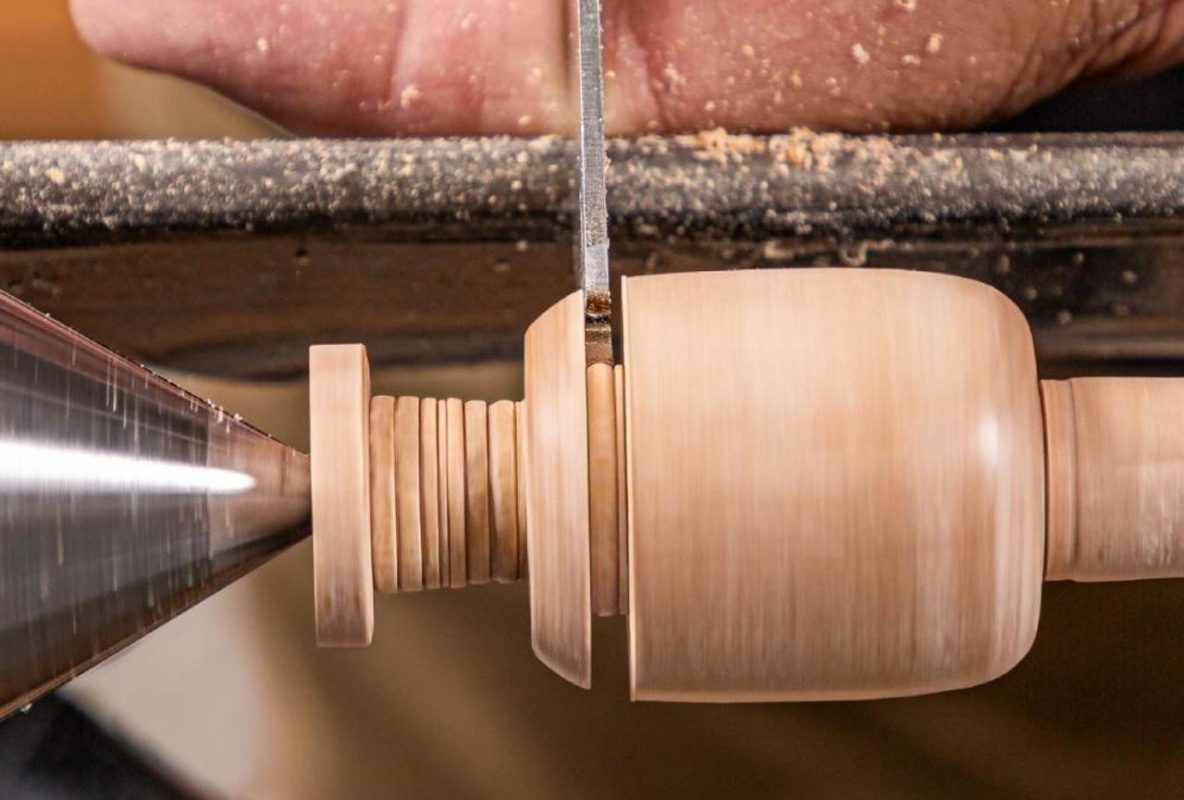

Parting or Cutting Off Operation

Cutting off is another operation that you can easily do using a CNC router you have purchased from a CNC router shop. During this operation which is extensively utilized in the fabrication of individual components from substantial stock, you can divide a specific section from a larger material body.

Not only does this method streamline the separation of components, producing individual parts from larger material segments, but it also fosters material conservation by maximizing the number of parts obtained from a single piece.

Facing Operation

The meticulous process of crafting a flat surface on a workpiece, typically initiated at the outset of the manufacturing journey is considered facing. CNC routers execute this task by deftly maneuvering a cutter across the material’s surface, thereby ensuring a uniform and polished finish.

This operation is paramount for preparing materials for subsequent machining or for achieving the desired aesthetic qualities. That’s why the CNC router with all its equipment must be purchased from a good CNC router shop to make sure the machine is of high quality.

Chamfering Operation

Sometimes you need to remove a small segment of material to create a beveled edge either for aesthetic or functional purposes, such as facilitating assembly. This operation which is called chamfering needs to be done by precise and adaptable CNC routers.

This process can be customized to accommodate various angles and depths, contingent upon the specific requirements of the project.

Inlaying Operation

Last but not least from the many techniques you can do with CNC routers available in CNC router shops, comes the inlaying operation which involves the embedding of one material within another, creating decorative patterns, or enhancing an object’s structural integrity.

The applications of inlaying are varied, including the creation of complex patterns and artwork for furniture, musical instruments, and decorative items, as well as strengthening objects by incorporating materials with specific properties in critical areas.

Conclusion

CNC routers are incredible machines that handle various tasks, from engraving and profiling to 3D carving and inlaying. To achieve the best results, it’s crucial to invest in high-quality machines from a trusted CNC router shop. A reliable CNC router unlocks your project’s full potential to ensure accuracy and efficiency. Regardless of what you tend to do such as exploring art, industrial manufacturing, or custom designs, CNC routers are the way to go in fabrication and craftsmanship.